Call Us Now

TEL: +86-4000988557;

Teams: gfreex@hotmail.com;

WeChat: Troysupply_com;

QQ ID: 8936906.

Industrial 6 axis robot arm training platform training targets:

*Usefully running 6 axis robot arm by program

*Usefully for I/O control with robot gripper

*Usefully for connection with PLC

*Usefully for daily maintenance

Item No.:

TRE500S-TPPayment:

CIF / FOBProduct origin:

ChinaColor:

Blue Black RedShipping port:

ShenZhenLead Time:

15Min order:

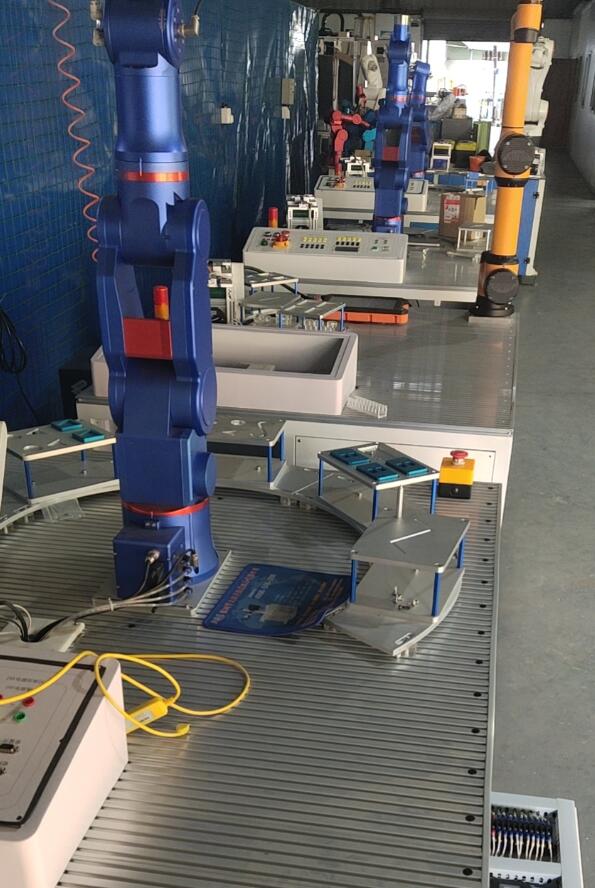

5Instruction of six-axis robot training teaching platform

First: Introduction

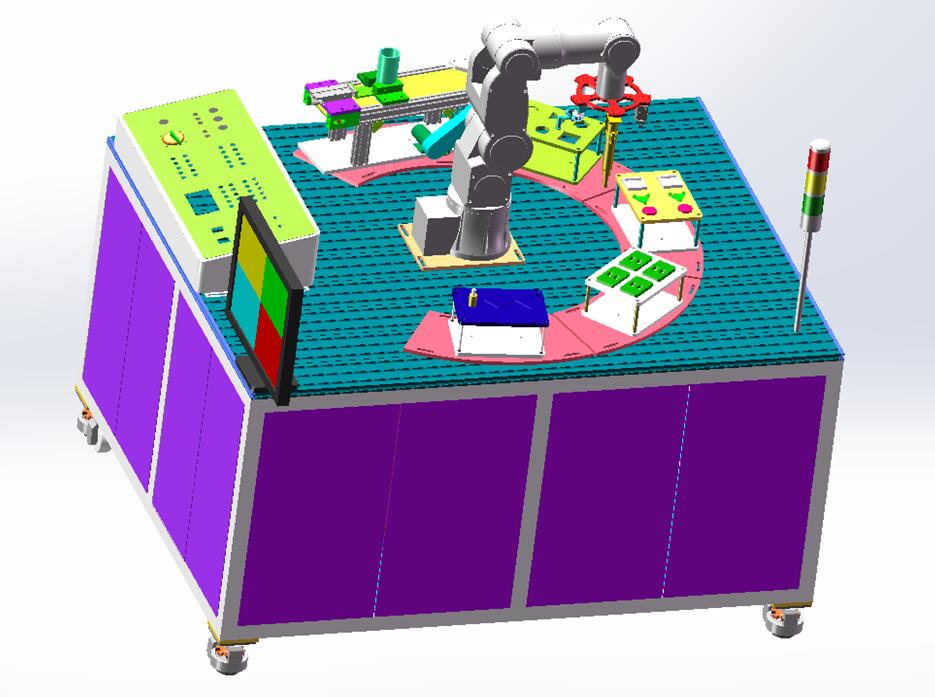

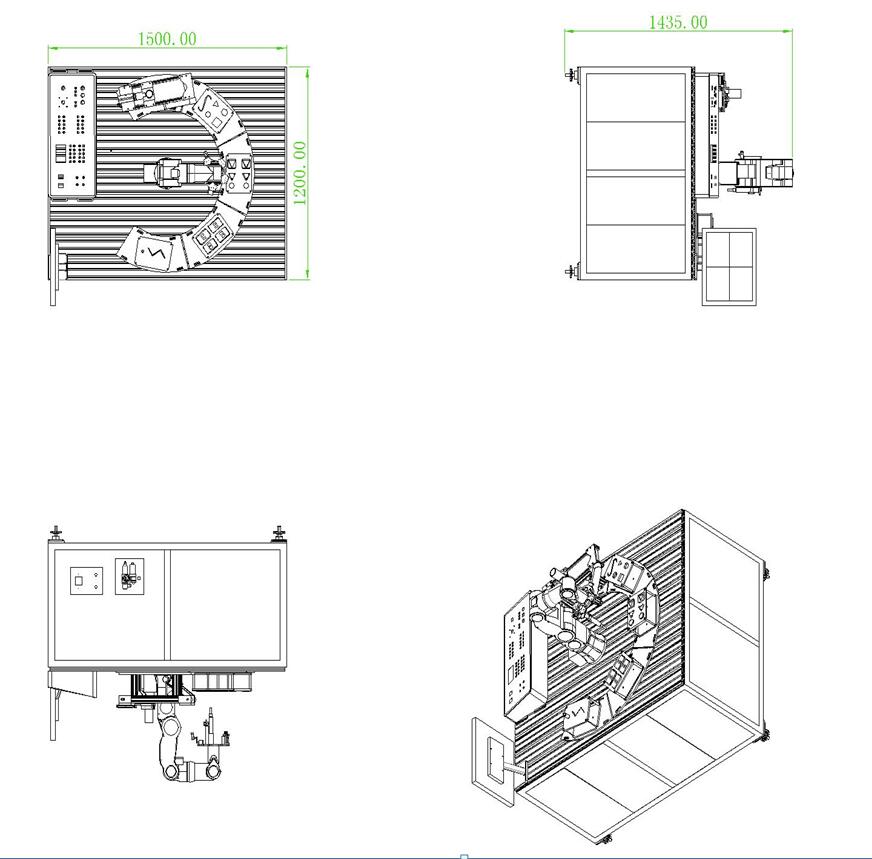

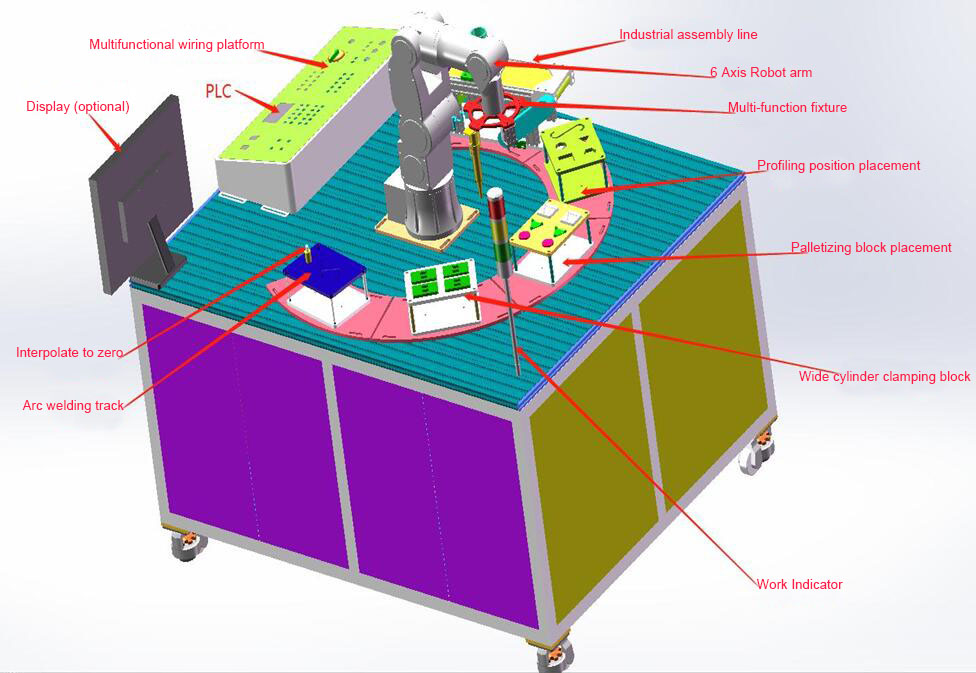

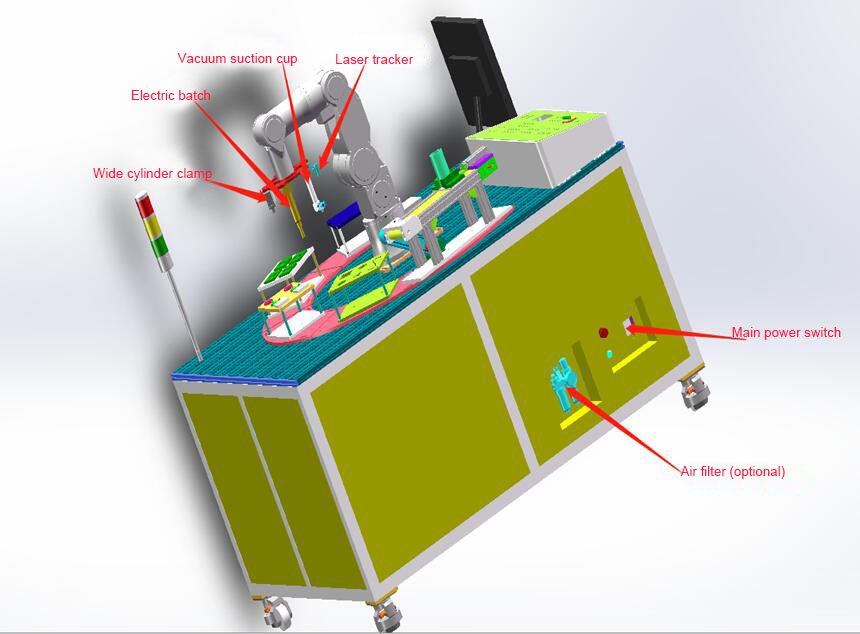

This robot teaching and training workstation is based on a robot, equipped with corresponding peripheral modular accessories, mainly including: industrial assembly line, palletizing handling, welding track module, material clamping, positioning pin, vacuum suction and detection.

Third: Instructions for each functional module (1)

Instructions for each functional module (2)

Fourth: Description of the action flow of each functional module

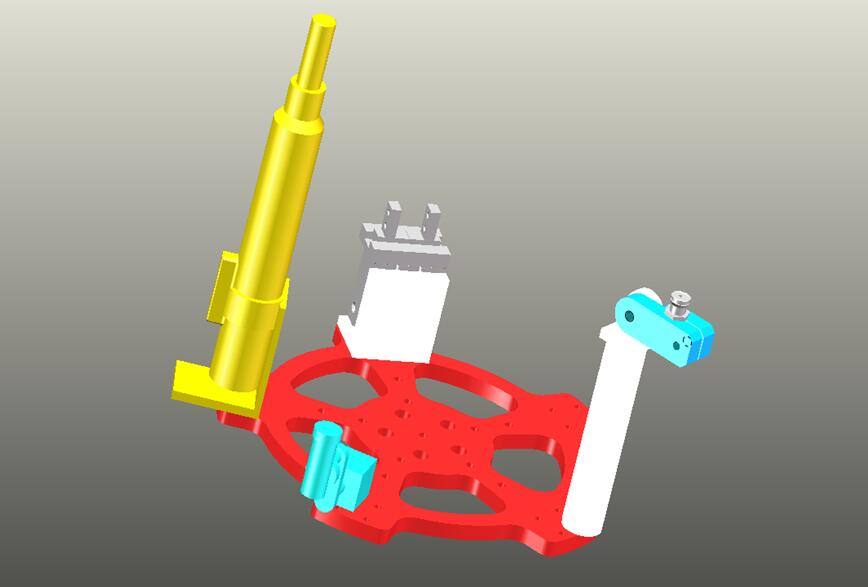

4.1 Multi-function fixture

4.2:

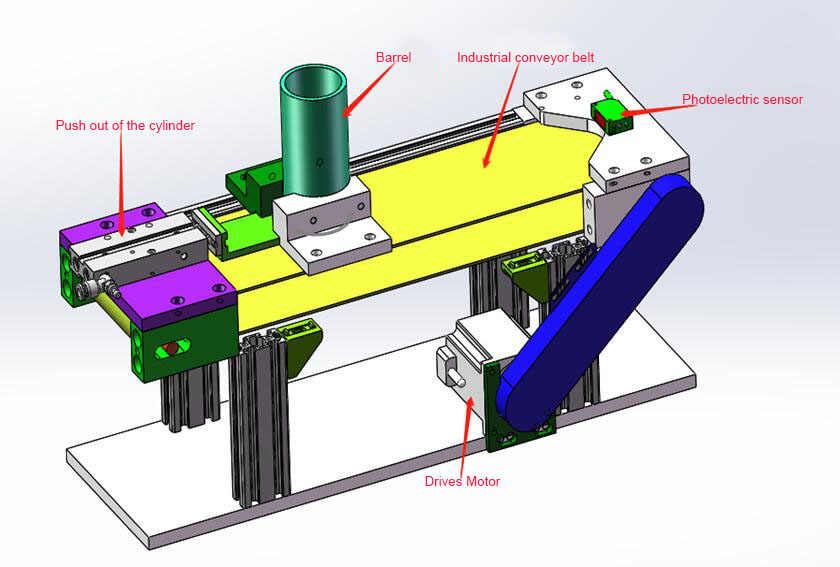

Industrial transmission belt

Operation process description: the cylinder pushes the round block and falls

onto the conveyor belt, the belt transfers the round block to the front baffle

position, the sensor senses that the round block is in place and sends a signal

to the PLC, and the PLC controls the belt to stop the transmission movement

Move to the top of the round block and take it.

4.3:

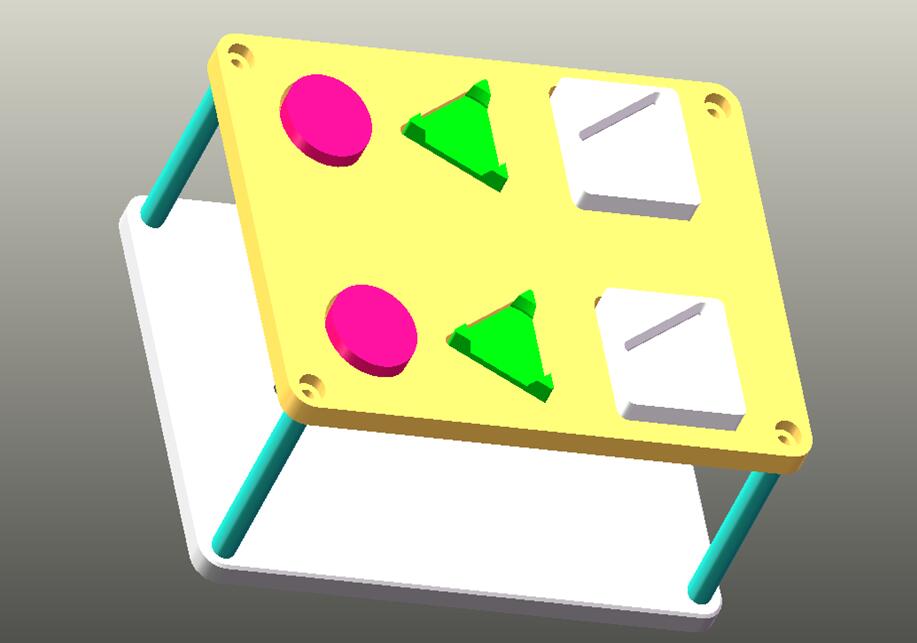

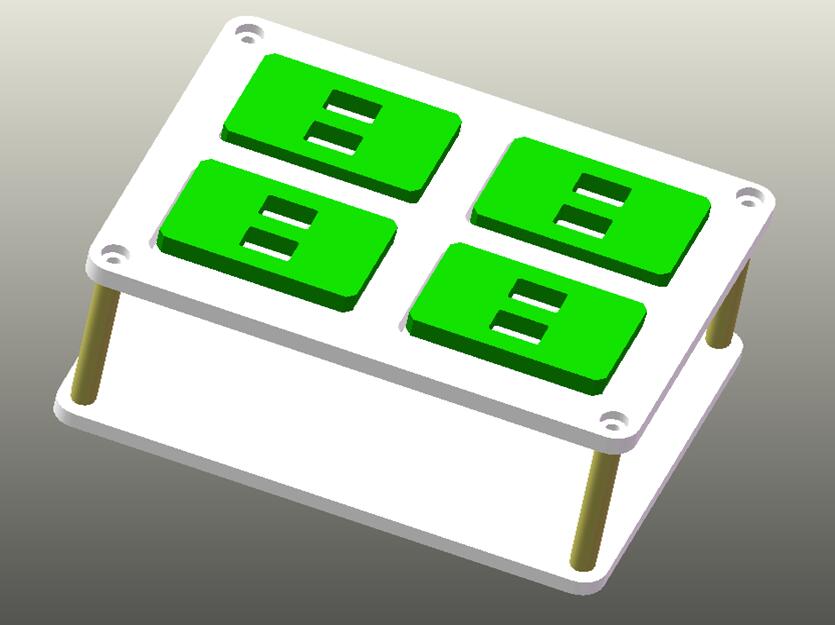

Palletizing platform

Operation process description: The vacuum sucker sucks the triangle into the

square block. Then suck the circle into the triangle, and then put it back to

the original position.

4.4:

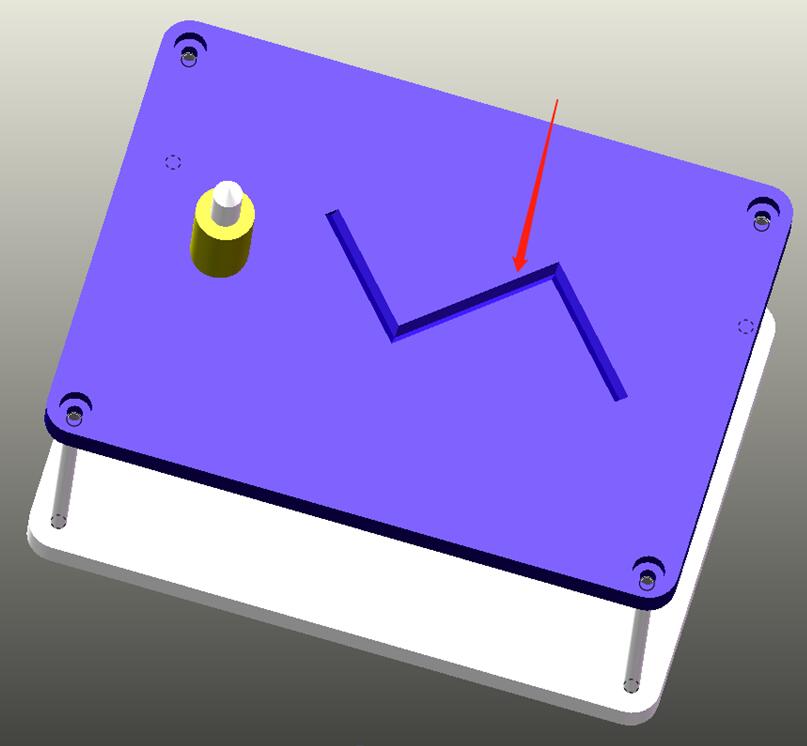

Needle and arc welding track simulation

Action flow description: The manipulator moves the arc welding simulation

column (laser pointer) to the Z-shaped trajectory, and the manipulator controls

the column to walk along the trajectory.

4.5:

Cube gripping

Action flow description: The robot moves the wide cylinder gripper to the top

of the block, descends and clamps the block to the specified position.

Fifth:

Button description

Emergency stop: Control the robot to stop (press it to stop, turn it on and

press the start button to continue following the program.) Power: Control the

robot power management. Start: Control the robot to move according to the

program. Zero return: control the robot to return to the programmed zero

position.

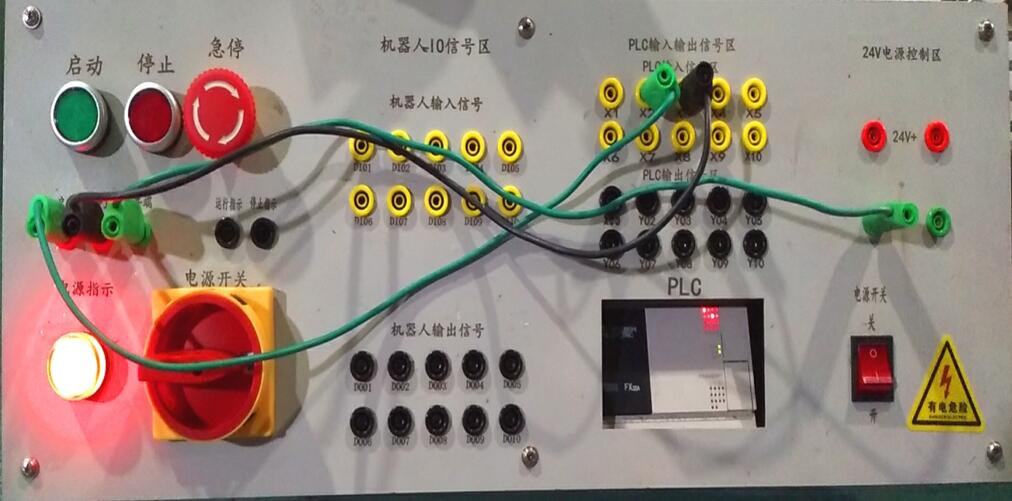

Sixth:

Description of control wiring board

Through this controller, the communication between the robot and the PLC can be

easily realized, and at the same time, the wiring method and skills can be

understood intuitively. Through the connection of various input points, the

construction of various settings can be quickly realized, which is convenient

for learning and safe.

Seventh:

Repair and maintenance

One: Please turn off the main power supply before repairing the equipment.

Non-professionals should not open the power box.

Two: Please clean the work surface and turn off the main power and air source

after each use.

Three: Before operating the equipment, please pay attention to the environment

within the robot's movement radius to avoid safety accidents!

The 6 axis robot Support PC, mobile phone, teach pendant, voice, APP, and other intelligent interactive control methods.

TRE06P 6 axis educational robot can be used for high school, robot engineer training school purpose.

The TRE500S body joint is made of high-strength aluminum to ensure the machine's high strength, high speed, high accuracy and high stability.

EDU Robot Applications: Commercial robots, teaching robots (teaching robots for universities, middle schools and elementary schools), collaborative six-axis robots, photographic camera robots, beauty and body robots, milk tea robots, auto parts, elevator parts, auto parts inspection tools, precision hardware, medical equipment accessories, etc.

Applications include CNC machining centers, CMM measurement centers, CNC lathes, wire cutting, milling machines, grinders and other equipment, and can be used with various surface treatments according to customer requirements.

Main product applications: commercial robots, teaching robots (teaching robots for universities, middle schools, and elementary schools), collaborative six-axis robots, photography and video robots, beauty and body robots, milk tea robots, auto parts, elevator parts, auto parts inspection tools, precision hardware, medical equipment accessories, etc. .

Main Products: Commercial robots, teaching robots (teaching robots for universities, middle schools and elementary schools), collaborative six-axis robots, photography and video robots, beauty and body robots, milk tea robots, auto parts, elevator parts, auto parts inspection tools, precision hardware, medical equipment accessories etc.

TR5-850 is a 4-axis vertical multi-joint robot with an effective punching load of 5KG. It can adapt to a variety of different application scenarios, and can customize five or six axes according to customer needs. The TR5-850 product is easy to understand and has a solid structure to meet the requirements of customers for product diversification, high efficiency, and product production.

TRE5-8CO is a 6-axis vertical multi-joint Cobot with an effective load of 5KG. It can adapt to a variety of different application scenarios, and can customize five or six axes according to customer needs. TRE5-8CO Cobot is easy to understand and has a solid structure to meet the requirements of customers for product diversification, high efficiency, and product production.

Digital Microscope TVN-600II main features: (1)Magnification knob: Rotate the magnification knob to make the image the right size on the display, depending on the size of the product (2)Light source: Ring light source (3)Up and down adjustment knob: adjusts to the height of the product to give a clear image (4)Light source adjustment knob: adjusts the level of brightness of the light source (5)USB port: can be connected to a USB mouse for operation and a U disk for saving pictures

In addition to the vertical take-off and landing functions of conventional rotor drones, the dual-rotor series UAVs also have the advantages of compact structure, small weight, high portability, high efficiency, and long endurance. Suitable for reconnaissance, public safety, military and intelligence missions.

AM600 series medium-sized PLC Applicable industries: High-speed printing equipment, lithium battery winding, high-speed lamination, new energy industry multi-axis bus control production line, coating inspection, packaging, labeling, etc.

TR-M630/10 transformer model features: A 630kVA oil-immersed transformer, has become a classic choice in medium and low voltage power distribution due to its high cost-effectiveness, reliable performance, and maintenance-free operation. If you are looking for an economical, practical, stable, and durable power distribution solution, the TR series is a wise choice.

Cobot CS612 Parameters: Six degrees of freedom, weight 33kg, load 12kg Working radius 1304mm Repeat positioning accuracy ±0.05mm Maximum speed 3.0 m/s Typical power 500W Protection grade IP54

Electron Metallographic Digital Microscope TVN-MT60_B of main features: The atmosphere is stable and the operation is more flexible. It integrates various observation functions such as bright field, dark field, polarized light, and DIC differential interference, which can be selected according to actual applications.

SRC-based laser SLAM stacker automatic forklift TR-FL300P, equipped with SRC series core controller, can identify pallets, fork goods accurately, and operate efficiently; and adopts laser SLAM navigation, no reflector, easy to deploy; fuselage 360 °Comprehensive protection + 3D obstacle avoidance to improve the safety of robot operations; the lifting height can be customized, which is a "stacking weapon" in the factory; the maximum load is up to 3000kg, suitable for large factories or warehouses. Load handling, stacking and palletizing scenarios

Commercial Fully Automatic Fried Egg Machine: This is fully automatic Fried Egg Machine features touchscreen control and intelligent temperature control, and can make approximately 1-120 eggs per hour. You can choose between medium-rare, medium-well, and well-done, freeing up your hands and meeting the needs of a wide range of customers.

Terminator humanoid AI Robot TR-T800 Size Specifications: Height: 173 cm Weight (including battery): 75 kg Total Degrees of Freedom (excluding dexterity hand): 29 Single Hand Degrees of Freedom: 7 Lower Leg + Thigh Length: 91 cm Arm Length: 60 cm Neck Degrees of Freedom: 2 Single Leg Degrees of Freedom: 6 Waist Degrees of Freedom: 1 Single Arm Degrees of Freedom: 7

3D Handheld Scanner Applications: Ø Automobile manufacturing Ø Aerospace Ø Power generation Ø Model manufacturing Ø Casting inspection Ø Construction machinery Ø Design inspection Ø Architecture sculpture

MG500 Rally Motorcycles are designed for off road users, it's can be rided on both high road and off road

We can fast supply the used LNG tanks to world wide! China Used LNG Tank supply from 30m³/50m³/60m³ etc. Since the year 2015/2016/2017...

Yaskawa Scara Robot SOC series: The MOTOMAN-SOC series is a SCARA robot specially built for high-speed operations. It is suitable for various scenarios such as assembly, transportation, packing, sorting, and inspection of small parts.

Water jet cleaning robot TRWJR-HM_V series: The ship rust removal robot is an automated equipment, mainly used for rust removal on the surface of large steel structures such as ships. This robot combines ultra-high pressure water jet technology, magnetic adsorption and wall climbing robot technology to achieve efficient and environmentally friendly rust removal operations. At the same time, it combines vacuum recovery technology to achieve wastewater recovery, reduce the discharge of paint residue and rust residue wastewater, and achieve environmental protection purposes. The application of this robot not only improves the efficiency of rust removal work, but also greatly reduces the potential risks to the environment and the health of operators, showing its important role in modern industrial maintenance.

CNC9620 CNC Lathe machine control system Introduction: ADTECH specifically for small and medium sized machine tool manufacturers both in domestic and abroad independent research and development of cost-effective CNC control system. Use ARM high performance CPU and super-large-scale programmable device FPGA, real-time multitasking control and hardware interpolation technology to ensure high efficiency of the system under the um-level precision machining. 256M electronic panel meets variety of large program work pieces. 7 inches color screen, interface can be made of parameter selection in both Chinese and English.

Robot arm Applications: ——Material handling and palletizing Greater flexibility, more stable performance, and lower energy consumption; Maximum throughput with high-speed performance; Long working time; Fixed automation

This equipment is a high-quality product developed by ourselves according to market demand after learning the advantages of European models. Mainly used for packaging medical disposable nitrile/latex gloves. Continuous model, easy to operate and good stability. Newly improved air blasting device, the finished product is smooth and beautiful.

The TVN-2K30/4K30 high-definition industrial camera is easy to use, featuring a built-in personalized interface editing function, template application, mouse operation, USB flash drive storage, and includes functions such as automatic edge finding, automatic contouring, horizontal and vertical flipping, line/circle calibration, data export, and playback browsing. It also provides various measurement tools such as "parallel lines," "point-to-line," "concentric circles," angles, and radians.

Tea Packaging Machine Features: Sealing material: PVC Applicable objects: All kinds of tea Total product weight: 180kg Fully automatic Product size: 75*70*150cm Rated power: 0.8kw

Feed Packaging Requirement: Bag form user provided Single package net weight 25-50kg Single equipment packaging capacity 280-380 bags/hour

Robot Features: Configure 300ML special silicone barrel Precise glue dispenser, accurate glue application, quick glue reaction Suitable for silicone, yellow glue, white latex, glass glue, sealant, etc. Chemical resistance, strong durability, balanced coating lines At the end of each dispensing cycle, there is a suction force to solve the serious problem of glue drawing.

The autonomous mobile robot TR-Max600L based on visual perception has a more dexterous body and can move freely in small spaces to meet the needs of all-scene operations. Support low obstacle and dynamic obstacle detection to meet the needs of people and vehicles mixed operation. Unlock more application scenarios through a variety of bodywork modules.

Killerbody Bumblebee Helmet features: Unit weight: 1.8kg Product volume: 38cm * 38cm * 38cm Material: ABS Function: music/voice, deformation switching, bluetooth audio Origin: Mainland China Brand: killerbody Product Category: Transformers Control method: voice control Whether electric: yes Power supply mode: battery Packing: color box Anime Character: Bumblebee

Coffee Maker Robot Features: Customer selects the coffee drink on the touch screen, and submits the order after the selection. Our Coffee Cobot system immediately receives the order information, and the Coffee Robot starts making coffee according to the order information.

Amphibious UTV features: Hull material: fiberglass Model: TR-AUTV04 Specification: 1500cc Air pump: yes Maximum number of occupants: 2 Maximum load: 200kg

Balance Crane features: 1. The operating range is 7 meters, and the market is generally 5 meters. 2. The lifting mechanism adopts the elevator principle, and the failure rate is low. 3. 360 degree free rotation, no dead angle. 4. 1.5KW motor, low energy consumption and low noise. 5. The appearance is electrostatically sprayed, which is beautiful and has good anti-corrosion performance. 6. It can be customized according to customer needs.

3D Digital Microscope TVN-800+P3D hardwares: The entire body (including the lens, LED light, and processing unit); 13 inch Screen; Accessories (DC power calbe for Microscope/screen, mouse, HDMI cable)

Easy to operate: Force-free techingeffectively reducesdebagging time and learning cost.PortablePC,friendly man-machine operation interfacemakes the robot easier to use. Modularity: All-in-one module of reducer,motor,encoderand drive,which is convenient for quickdisassembly. Quick deployment: 3kg in rated load with 13kg in weight.Light-weight installation and flexible deployment.

Laser Cutting Machine Advantages: System intelligent alarm Multi-directional abnormal alarm of equipment is directly communicated to the panel, so that equipment failures are known in advance, hidden dangers are reduced, and the efficiency of equipment abnormality investigation is doubled

Six degrees of freedom, weight 13kg, load 3kg Working radius 624mm Repeat positioning accuracy ±0.03mm Maximum speed 2.0 m/s Typical power 150W Protection grade IP54

1. This machine is an automatic headband type KN95 mask production line, which automatically produces multi-layer masks with double-fold ears; 2. Driven by Mitsubishi servo motor, with high stability; 3. The machine adopts branded ultrasonic welding machine, which has good welding effect, good stability and low failure rate; 4. Panasonic PLC programming control, servo control, high degree of automation, high output and good stability; 5. Intelligent material supply, through the installation of sensors, realize the detection of material production, and the machine will stop and sound an alarm when there is no material; 6. Nose line: automatic line feeding and cutting; 7. LOGO pad printing, special LOGO or pattern can be customized according to requirements; 8. Automatically realize left and right ear strap feeding, cutting load and ultrasonic welding; 9. Fold the fabric that has been processed in half in half; 10. Through the mold, the folded fabric is further processed into finished products

Passes signals with frequencies below the selected Cutoff Frequency and attenuates signals with frequencies above the Cutoff Frequency.

Terminator 2 Model T800 Red light of eyes T2 collection No removal chip in the head !

Similar your real girlfriend Customized body shape, face appearance and eye color options etc. Warm Body function Fluently English and Chinese speaking

4 Axis Industrial Robots are designed for punching machine, CNC machine feeding applications. OEM customers are more than welcome !

Compound Hunting BOW PARAMETER: Right handed, IBO 320fps; Axle-to-Axle: 31"; Draw weight: 19-70lbs, Draw length: 19”-30” adjustable,without bow press, Brace height: 7”, Let-off: 80%, Bow weight: 3.95lb

LiDAR 3D SLAM AGV features: 3D sensing, all-round security protection; LIDAR 3D SLAM AGV can be applied to factory automation, warehousing automation, port automation and other applications, taking automation operations to a new level.

4 axis delta robots are designed for food packaging in the production lines. such as chocolate, biscuit and bread factory makers.

Ultrasonic Models: 20K2000W; 20K2600W; 15K2600W. for one to 2 line face mask machine high speed one to 1line face mask machine KN95 face mask machine KF94 face mask machine

Robot Features: Large working space Stable performance Run fast Good general performance Modular mechanical structure design

*Biochemical defense *Tear gas defense *COVID-19 defense by N95 filters *Environmental pollution prevention *Airborne infectious disease defense

Rehabilitation Exoskeleton Robot: It can provide the most realistic walking gait, suitable for many diseases (including stroke, paraplegia, and other lower limb weakness disorders, with low requirements for upper limb strength), wear quickly, and electrically adjust leg length!

Capacity: 40-50pcs/min Power: about 11kw Weight: about 2000Kg Product size error: ±1mm (excluding raw material error)

Vacuum Degassing Mixer Description: While rotating and revolving, the machine, coupled with a high-powered vacuum pump, mixes materials evenly within seconds to minutes. Mixing and vacuuming are accomplished simultaneously. Equipped with various clamps and cups, it can mix materials ranging from a dozen grams to 1500 grams.

Online thermal imaging camera: TR-460TC is a high-performance, high-precision network-based thermal imager that uses an uncooled infrared focal plane array detector. Multiple lenses are available, providing clear and accurate infrared images and temperature measurement capabilities. TR-460TC supports various communication protocols including Modbus TCP, ONVIF, and GB28181, and comes with professional infrared temperature analysis software and SDK. Its small size and low power consumption facilitate system integration in machine vision, power, rail transportation, and industrial automation applications.

TR-SBA&TR-SBB Automatic glove dipping lines: Surgical Examinational Disposable Glove Dipping Machine and Glove Packaging Machine TR-SBA for single mold line TR-SBB for double mold line Suitable materials: PVC emulsion\Latex\Vlnyl Main products: PVC/Latex/Vinyl gloves for examination, surgery, disposable glove for household, and beading, straight (powder/ powder-free).

High Quality AC Servos for Robot build up or retrofiting CNC machines etc. OEM available to our customers, ac servo driver, ac servo controller

Similar your real girlfriend Customized body shape, face appearance and eye color options etc. Warm Body function Fluently English and Chinese speaking

Jacking AMR MINI Forklift Features: *European standard pallet Adaptable to EPAL European standard pallet *Dock-type docking Active telescopic fork arm *High safety 360° laser obstacle avoidance, fork tip protection, etc. *Narrow lane passage APR rotation in place

MIG and TIG welding robot for steel, stainless steel and alumium etc. OEM Robot customers are more than welcome !

Carton transfer unit automation unmanned picking and handling lifting by CTU AMR Robot: 6 layers by 50kg payload each layer; Integrated control, efficient and easy to use !

E-Cigarette features: *Standard test environment: Temperature: -5—42℃ *How to use: Pull the silicone of the atomizer mouthpiece outwards to expose the smoke outlet. Then remove the bottom sticker and start using it. (If the amount of smoke extracted is small, please replenish the battery in time)

From 500kg, 1Ton to 40 Ton Payload 6 feet steward Robots are available !

AI Reception Robot features: use: Restaurant & Hotel Supplies Place of Origin: China Model Number: TR-WS02 Color: Starry White/Starry Night Black Material: High Strength PC+ABS Size: 410mm*410mm*1000mm Applicable people: ALL Battery capacity: 10.4 Ah , 25.2 V Endurance time: 8h Net weight: 21.1kg Screen size: 14 inch

Abdominal Toning Belt features: * Smart phone controls * EMS IC chip * 8 difference mode * 50 levels * Auto stop by 25 minutes * One button operation

Electric push forklift features: Brand: OEM Steel plate thickness: fork 8mm Weight: 50kg Maximum lifting speed: 8cm/s Number of casters: 4 pc Caster Material: Nylon Plate thickness: 4cm Special industry: logistics industry / loading and unloading team / factory Load capacity: 500kg Fork Length: 90cm Model: TR-C01

The TRE500S body joint is made of high-strength aluminum to ensure the machine's high strength, high speed, high accuracy and high stability.

ADULTS MODEL Iumping Stilts: Aluminum alloy Fram with a half plastic pedal; Movable pedals; Loading body weight : 50-70KG, 70-90KG; 90kg-100kg. Colour: Black, blue, yellow, gray Packaging: 1 pair/ box packaging Net weight: 7KG

Unmanned Container Transport Vehicle features: The TR-CONT70S is a new generation of AI-powered container transport vehicle. It is lighter, lower, and narrower, allowing for better adaptation to horizontal quay unlocking processes. Equipped with an L4-level driving system, it efficiently interacts with quay cranes, rail-mounted cranes, locking stations, and automatic charging stations throughout the entire process, achieving cost savings of over 30% compared to traditional AGVs used in automated terminals.

Semi auto labeling machine applications: It can be used for labeling various specifications of cylindrical objects, such as red wine bottles, beverage bottles, xylitol, cosmetic round bottles, medical test tube oral liquids, etc., equipped with full-week/half-week labeling, and labeling functions on the front and back of the circumference; can be equipped Ribbon printers, inkjet printers, and labeling machines print production batch numbers and other information at the same time.

High speed and Reliable Delta Robots supply. It's build up with panasonic servos. Supports vision camera on production lines

Main product applications: commercial robots, teaching robots (teaching robots for universities, middle schools, and elementary schools), collaborative six-axis robots, photography and video robots, beauty and body robots, milk tea robots, auto parts, elevator parts, auto parts inspection tools, precision hardware, medical equipment accessories, etc. .

Anti drone device is designed for airport control, public safty control etc.

Earth Pressure Balance TBM: Muck is used as the main medium to balance the ground pressure on the tunnel excavation surface, and the slag is discharged through a screw conveyor. The excavation diameter covers 3 meters to 14 meters.

Product specification: Length 15m, Height 1.8m, Width 3.2m; Speed: 900 boxes/Hour.

Robot Features: Large working space High repeat positioning accuracy Stable performance Run fast Good general performance Modular mechanical structure design

TRE06P 6 axis educational robot can be used for high school, robot engineer training school purpose.

Robot Arm Applications: ——Spraying and cutting Stabilize and improve welding quality and ensure its uniformity; Improve productivity, continuous production 24 hours a day; Improve the working conditions of workers and work for a long time in harmful environments; Reduce the requirements on workers' operation skills; Shorten the cycle of product modification and replacement, and reduce the corresponding investment equipment; Can realize batch product welding automation; Save floor space.

*Stabilize and improve welding quality and ensure its uniformity; *Improve productivity, continuous production 24 hours a day; *Improve the working conditions of workers and work for a long time in harmful environments; *Reduce the requirements on workers' operation skills; *Shorten the cycle of product modification and replacement, and reduce the corresponding investment equipment; *Can realize batch product welding automation; *Save floor space. Main applications——Grinding and polishing Cutting, grinding, deburring, cleaning, polishing, water cutting and other processing applications

*Robot advantages: fast speed, high precision *Long service life and stable performance *Strong compatibility and strong flexibility *Simple control and ease of use

MIG welding robot for steel, stainless steel. Compatible with 1/2 axis Rotator table. Laser seems tracking system is available for this robot !

High-Speed Glue Spraying Cartoning Machine Specifications: Model: TR-ZC-G2 Conveyor Speed: 6000-9000 Pcs/h Carton Size (mm): L70-200*W35-85*H15-50 mm Power Supply: 220V/50Hz Machine Dimension: L6100*W1800*H2000 mm

Oxygen Machine Specification: Customize Production: Yes Extraction Gas type: Oxygen Workign Principle: Compression Processing capacity: 6.7 (m3/h) Dimensions: 355*275*370 (mm) Weight: 7.3-8.3 (kg)

The MINEBEE super mini drones are coming soon !!!

What does Robot Puppy do for you? Video surveillance, Visual line patrol, Ultrasonic obstacle avoidance, Self-balance control, Motion detection, Color recognition.

THE 4TH GENERATION of Robot Car Parking: The 4th generation of Parking Robot adopts the new patented design of center-positioned robot arms and differential driving units while the software and algorithm are also comprehensively optimized.In addition,Parking Robot has passed the acceptance test of CSEI (China Special Equipment Inspection And Research Institute),ensuring operation of robots in parking lots.

High-altitude Glass Wall Cleaning Robot Features: Robot size: 1377*1000*288 mm Traveling mode: Suction cup adsorption and wheel-type movement, automatic/manual travel possible Obstacle surmounting ability: Concave-convex height does not exceed 10 mm Cleaning efficiency: 720㎡/h Battery life: 3 H/battery (±30%)

2 axis rotation table for welding Robots * Payload from 200kg to 1000kg * Table diameter from 400mm to 600mm * Can be customized.

Equipment Principle: The galvanometer laser welding machine is a perfect combination of the galvanometer motion system and the laser welding machine system. The laser realizes the rapid movement of the laser spot through the oscillation of the galvanometer, so it can achieve high speed of any graphics on the welding plane within the welding range High-precision spot welding and continuous welding.

The MOS mobile collaborative robot itself is an operator that can move autonomously, Timely complete the tasks of multiple different stations in the production line. Using Mecanum wheel drive mode, Realize 360° movement in any direction, and can work flexibly in a small working space, effectively Improve site utilization and production efficiency. Through the matching of rich end fixtures and visual knowledge Different equipment, which can realize grasping, assembly, sorting, loading and unloading, moving, handling, vision Detection and other functions are more accurate, stable and efficient.

The MOD mobile collaborative robot itself is an operator that can move autonomously. Timely complete the tasks of multiple different stations in the production line. Using Mecanum wheel drive mode. Realize 360° movement in any direction, and can work flexibly in a small working space, effectively Improve site utilization and production efficiency. By matching rich end-fixtures and visual knowledge Different equipment, which can realize grasping, assembly, sorting, loading and unloading, moving, handling, vision Detection and other functions are more accurate, stable and efficient. Two-arm bionic design, more close to human operation mode, suitable for a variety of typical work stations that require both hands at the same time.

We offer video microscope solutions that make industrial inspection easier, more convenient and more efficient. At the same time, ergonomic issues such as operator comfort and wafer safety are particularly important when integrating microscope successfully into production lines, and we focus on addressing such issues. The company has been providing new ideas, solutions and technical support to a wide range of industries, including semiconductor wafers, flat panel displays and electronic devices.

Product Type: handheld game console: Game type: RPG role-playing, ACT action game, AVG adventure game Operating system: liunx RAM: 16G Interface type: USB Video/audio interface: HDMI Connection method: wired Additional features: MP3 music player Video game classification: Fever, Elite, Hardcore

Unmanned Delivery Robot: The second-generation high-performance TR-UB003 unmanned delivery vehicle, designed specifically for open roads and campus terminal delivery scenarios, has L4 level autonomous driving capabilities and can achieve the last five kilometers of delivery to the user.

Water drone with camera: *4 working hours *Water depth 30 meters *Fish finder device *VR glasses supports

Cartoning machine, unpacking machine, cartoning machine, carton sealing machine, sealing machine, palletizer, strapping machine, film wrapping machine and assembly line whole plant packaging scheme customization, which can be applied to: food, daily necessities, cosmetics, toys, electronics, Chemical and pharmaceutical, stationery, building materials, hardware and other industries. All series of products are sold all over the country and exported to America, Europe, South Africa, the Middle East, Australia

SE01 overcomes the natural gait problem that has long restricted the development of humanoid robots. In many people's impressions, robots often give people the impression of "broken steps, bent legs, and chopping feet" due to technical deficiencies, but SE01 completely subverts this stereotype, allowing robots to walk freely with a steady, fast and smooth pace. SE01 can show unprecedented elegance and energy saving in both static and moving states, thus greatly shortening the behavioral performance gap between robots and humans.

Product Features 1. The cold generation aerosol generator is used to generate continuous and stable aerosol particles, and the filling of the aerosol is simple and convenient. 2. Use two sets of high-precision aerosol particle detection sensors to measure the upper and lower chambers simultaneously. 3. Configure the salt particulate aerosol generator. 4. Equipped with aerosol particulate static neutralization device. 5. Configure high-precision digital gas flow sensor to accurately measure gas flow. 6. Configure industrial-grade temperature and humidity sensors to accurately measure the ambient temperature and humidity in real time. (Test condition: 25 ± 5 ℃ 30 ±10% RH) 7. 10 inch touch screen, the operation is simple and clear. 8. Pneumatic fixture, easy to change samples. 9. Pumping and exhausting integrated silent vacuum pump, no external air source needed. 10. High-precision pressure gauge and flow regulating valve can adjust aerosol concentration. 11. Micro printer can print detection data. 12. Intelligent configuration such as leakage protection, overload protection, power-off preservation, etc., effectively protect the safety of use. 13. Special test software can be connected to the computer.

Scope of application for checking weight machine: Automatic Weight Machine is suitable for testing whether the weight of a single product is qualified, and is widely used in electronics, pharmaceuticals, food, beverages, health care products, daily chemicals, light industry, agricultural and sideline products and other industries. Such as conditioning products, pastries, ham sausages, instant noodles, frozen foods, food additives, pigments, modifiers, preservatives, etc. in the food industry.

Dumpling Machine Specifications Dimension: 3400*2850*2000 Model: ZK-3-SJ Generation rate: 14000/hour Output: 280kg/hour Power: 12.9KW Power: 380V 50Hz(3P)

The TR-BOTRH/LH series of dexterous hands have strong gripping force and moderate speed, and are suitable for grasping operations of robots or prosthetics. Supports ROS and provides ROS plug-ins.

Cnc Milling 4 Axis Controller In China CNC9640 1.CNC9640 is 4 axis milling/drilling controller 2.CNC milling controller with 7 inch screen 3.can work together with addtional panel and handhold box

Mobile Robot Platform parameters: Curb weight: 70KG Max payload: 80KG Geometric size: 974.16*782.02*364 (mm) The fastest speed: 7.2km/hour Obstacle surmounting ability: 130mm Motor parameters: 4*400W brushless servo motor Communication interface: CAN/232 serial port Climbing angle: <30° Turning radius: 360° in place Battery: 48V30AH lithium battery

The Aerial Shuttle is a new IoT-based aerial logistics system. It consists of intelligent scheduling and monitoring software, standard track components, intelligent rail trolleys, and track switching. The entire system utilizes a modular design, allowing the planning and design of each unit to be combined to create a customized logistics system that meets the needs of customers and on-site construction.

Soldering robots are designed for the factory with electric components assembling such as Samsung, Foxconn, LG and Canon etc.

Tracked drainage and water supply Robot: Drainage and water supply robot is mainly used for flood drainage and rescue in limited urban spaces, such as underground parking lots, underground shopping malls, basements of residential buildings, subway stations, tunnels, culverts and underpasses.

Carbon Crystal painting heater features: Rated Voltage: AC220V+/-5%, 50HZ Power: 500w Frame: Alu frame Certification: CE, RoHS Working life: >100,000 hours Overheat protection: Yes Electric conversion rate: 98% Heating element: carbon crystal Infrared heater type: electric Leaking current: below 0.01ma Screen temperature: 70-85°C Heating area per pc: >20m2 Color: painting/picture/pure white Installation: Wall Mounted, Freestanding Function: Intelligent Adjustable Thermosta OverheatProtection

Quiet Industrial DC Fan features: *Copper wire motor *Super quiet bearing * Low power consumption and environmental protection * Flame retardant material

10KW wind turbine power station main ranges including the body, controller, inverter. Need batteries, solar panels or towers. 10KW wind turbine can be used for TV, lighting, electric fan, washing machine, refrigerator, rice cooker, water pump, air conditioner, and small village lighting.

The high configuration of our Delta Robot ensures with high performance and high cost performance: *By using imported from Japan's Panasonic servo motors. *by High precision planetary reducers. *Payload from 1kg to 15kg. *Working Diameter from 350mm-1400mm.

The intelligent digital ultrasonic welding system is mainly used in the fields of face mask machine, medical protective clothing making, diapers, non-woven bags making machine, non-woven clothing stitching, trademark slitting and nylon band cutting, etc.

Metal laser cleaning machine, also known as metal laser derusting machine, is a handheld laser cleaning equipment and a new type of high-tech machine for surface cleaning. It can work without chemical reagents, medium dust and water.

Easy to operate: Force-free techingeffectively reducesdebagging time and learning cost.PortablePC,friendly man-machine operation interfacemakes the robot easier to use. Modularity: All-in-one module of reducer,motor,encoderand drive,which is convenient for quickdisassembly. Quick deployment: 5kg in rated load with 18.5kg in weight.Light-weight installation and flexible deployment.

【Model】TR1030B-185 【Action type】Multi-joint type 【Rated load】30kg 【Motion radius】1850mm 【Weight】230kg 【Number of axes】4 axes

AUBO-i16 collaborative robot has a payload of 16kg. Max. length 1130.5mm, Max. Reach 967.5mm. Large payload, small size.

Collaborative Service Robot Applications: 1, Bar/Pub as a bar tender 2, Production line assistant 3, Demonstration / Showroom

Quiet Industrial DC Fan features: *Copper wire motor *Super quiet bearing * Low power consumption and environmental protection * Flame retardant material

Similar your real girlfriend Customized body shape, face appearance and eye color options etc. Warm Body function Fluently English and Chinese speaking

Six degrees of freedom, dead weight 17.5kg, load 6kg Working radius 914mm Repeat positioning accuracy ±0.03mm Maximum speed 2.8 m/s Typical power 250W Protection grade IP54 Collaborative Robot is designed for safety concept. Human and Robot can be working at same production lines together.

One-button measuring Mini AOI are widely used in industry: Including machinery, electronics, mold making, injection molding, metals, rubber, low-voltage electrical appliances, magnetic materials, precision stamping, connectors, terminals, mobile phones, home appliances, printed circuit boards, medical devices, and watches etc.

The Stratospheric Floating Wind Power System offers a renewable electricity solution that surpasses existing energy systems in terms of comprehensive cost and stability. It is the world's only disruptive renewable energy system to enter commercial operation, aiming to become the energy core of humanity's Fourth Industrial Revolution.

Luxury Yacht Specifications: Product name: 110-foot luxury yacht Product No.: MHY110 ′ Main scale: 33.30 × six point eight zero × 2.50m Host power: 670Hp × 2 sets Crew: 25 Draft: 0.90m Speed: 22kn Navigation area: Coastal

Navigation method: Magnetic navigation, Magnetic stripe Control method: Integrated controller Motor: Brushless motor, ≤200W / set Drive method: Differential drive Load method: Latency AGV

【Model】TR1006A-15MZ 【Action type】Multi-joint type 【Rated load】6kg 【Motion radius】1500mm 【Weight】150kg 【Number of axes】6 axes

Robot Features: Large working space Stable performance Run fast Good general performance Modular mechanical structure design

Composite Cobot Solution: TR composite robots are applied across numerous industries, providing innovative, efficient, and competitive overall intelligent manufacturing solutions that enable enterprises to achieve higher production efficiency, reduce costs, and bring about innovation to target industries.

Applications: ——Material handling and palletizing Greater flexibility, more stable performance, and lower energy consumption; Maximum throughput with high-speed performance; Long working time; Fixed automation.

Phosphor Bronze Ball Upsetting Machine parameters: Upsetting Phosphor Bronze Ball Diameter Range: φ50-φ60mm Extrusion force: ≥120t Production efficiency: ≥8 capsules/minute Total weight of equipment: ≥10t Yield index: ≥99.9% Power consumption: ≤45Kw.h/t

Floor cleaning Robot: It's relying on mature SLAM robot autonomous positioning and navigation technology, through the collision avoidance design of lidar + 3D camera,precise navigation and positioning, replacing manual labor with robots, reducing the difficulty of ground cleaning, improving cleaning efficiency and quality, Easily competent in various complex large scenes, with the advantages of simple operation, comfortable use, high efficiency and speed, etc., it has become the new favorite in shopping malls, hotels, high-speed railway stations and other fields.

Mini Electric Forklift Introduction: Smart Forklift is designed to lift standard pallet with 500kg load capacity and 3000mm lifting height. Mini Electric Forklift is an ideal facility to load/unload goods in stacking warehouses, super-market, workshops, production lines or handle goods on/off trucks, containers, etc

Similar your real girlfriend Customized body shape, face appearance and eye color options etc. Warm Body function Fluently English and Chinese speaking

Commercial Cleaning Robot: It adopts full 3D navigation and "modular" programmable design to specifically solve the cleaning operation problems in commercial scenarios. Can be widely used in hospitals, shopping malls, campuses, exhibition halls, office buildings, terminal buildings and other places.

1. The motherboard has 3188 games built in, including 100+ 3D games 2. The memory card is 32G, running with 4 cores without freezing or crashing 3. Support to pause the game midway 4. Quick search game function 5. Support 4 handles online 6. Button custom sorting 7. HD LCD screen 8. Support multi-language switching

* 5 axis laser cutting machine * 1.8G acceleration * Compatible pipe diameter from 6-115mm * Round Pipe, Square Pipe, Rectangular Pipe, Oval Pipe etc. * Laser power from 1kw - 3kw.

Laser SLAM Small Stacker Automatic Forklift TR-CDD14: SRC-based laser SLAM small stacker automatic forklift, equipped with SRC series core controller inside; using laser SLAM navigation, no reflector, easy to deploy; pallet identification, accurate forklift; flexible scheduling, can be seamlessly connected to the scheduling system ;Slim body, small turning radius, suitable for narrow channel applications; 360° three-dimensional safety protection with 3D obstacle avoidance, safety touch and other sensors, which is the only one for the handling, stacking, stacking and other work requirements of Sichuan-shaped pallets choice.

TVN-3D9000 with 3D deep view measuring features: *High-quality optical system *HD lens *Multiple obiective selection *Stereoscopic 3d imaging *High-precision measurement *Quality assurance

1. Application scenario: Automatic production of 4-6 layers folding masks. 2. Basic functions: A. Folding masks are produced by the whole machine in automatic assembly line. B. Automatically install the nose bridge, edge banding, forming and welding. C. Automatically printing logo, cutting ear straps, ultrasonic welding. D. Automatic folding, welding, cutting, leveling and shipping.

TaiWan famous brand servos drives A2 and B2 series

* Delta robots are cost-effective, high-quality and low-cost, can be customized OEM design for customers, and support various visual sensor information; * TRD robot application system is mainly composed of three parts: robot, wire feeding and robot installation frame. The robot consists of a substrate, a motor cover, a rotating shaft, a main robot arm; it is composed of auxiliary mechanical arm and gripper center.

Backpack-mounted AMR Mobile Robot: Category: Logistics and Warehousing AMR/AGV Equipment Industry: Handling/Loading/Unloading | Other Wheel System: Mecanum Wheels Load Capacity: 20-30 tons Navigation Method: Laser Navigation.

1. RTX3060 6G GDDR6 ultra high performance graphics card 2. The latest tenth generation Core 6-core i5-10400 high-performance CPU 3. Colorful backlit keyboard, 1920*1080 Full HD 144Hz 45% IPS screen 4, 8GB DDR4, 512G SSD mass storage

This solution's topology primarily encompasses front-end pretreatment, UV curing, and repair acceptance. Pre-treatment includes equipment such as pipeline inspection robots, cutting robots, and high-pressure endoscopes. These devices efficiently inspect and pre-process the original pipeline's condition, providing data-driven decision-making for subsequent UV curing repairs. Trenchless UV curing technology allows for rapid and precise pipeline repairs, extending pipeline life.

Automatic Strapping Machine Features: The automatic strapping machine has the advantages of high mechanical manufacturing precision, rigorous structure, firm packing, fast speed, low failure rate, and long life. It can be used in conjunction with an assembly line to realize automatic packing.

Feeding → Screw Extrusion → Melt Filtration → Metering Output → Die Head Extrusion → Into the Spinneret → Hot Air Traction → Net Curtaining → Electret Processing → Rewinding

Autonomous navigation, flexible obstacle avoidance, routes, trajectories can be set arbitrarily. Cyclic Sweeping & scrubbing in heavy polluted areas until all areas has been cleaned.

TH08R Spring Control System is a multi-functional, economical embedded numerical control system developed by Adtech, it's for 2-4 axis universal machine, spring compression machine, and spring torsion machine.

Engine:4 Stroke; Seats:3; Horsepower:> 300hp Cylinders:4; Engine Capacity:1300cc;

Baby Diaper machine Standard specification: 380x280 420x320 480x320 520x340; *PLC control system,Operating on the touch screen,Configure HDTV monitor; *Germany BST automatic web guide system (optional).

1) 4-axis CNC milling Center 2) 7.0 inch color LCD display screen 3) New design model 4) ATC and macro function

All-round AI Robot, defining a new level of operation: Faster, smoother, and safer, TR-S1 pioneered an AI-oriented integrated hardware and software system architecture. Deeply coupling "AI intelligence" with "strongest operation", it can learn, think, and work like a human, and interact with people safely and intelligently.

Anti drone device is designed for airport control, public safty control etc.

MIG/TIG welding robot can be worked as radius on 1850mm, suitable for chairs or furnitures welding !

GH-CNC820 is 4~6 axes economic type CNC spring making controller, it is specialized to compression spring machine, torsion spring machine. It has 5.7 inch LCD display screen and English application software.

SAR130 is a 4-axis vertical multi-joint robot with an effective punching load of 130KG. It can adapt to a variety of different application scenarios, and can customize five or six axes according to customer needs. The SAR130 product is easy to understand and has a solid structure to meet the requirements of customers for product diversification, high efficiency, and product production.

ADT-8940A1 is high cost effective pci-bus motion control cards. It support linear, arc. interpolation.40 channel input and 16 channel digtial output port. It can be application for cutting machine, engraving machine,laser equipments.

AUBO-i5FB collaborative robot can meet the needs of lightweight operations. Payload 5kg, Max. length 1008mm, Max. Reach 886.5mm. Wide application range, rich configuration, the end can realize ±360°rotation.

【Model】TR1006A-20MZ 【Action type】Multi-joint type 【Rated load】6kg 【Motion radius】2000mm 【Weight】170kg 【Number of axes】6 axes

ADTECH 3-6 Axis dispensing control system for high-precision motion control system.

AM400 series medium-sized PLC Product performance: Built-in EtherCAT bus *Can bring 4 or 8 servo axes (am401 can bring 4 axes, AM402 can bring 8 axes), support synchronous positioning, electronic cam, interpolation function. *Can expand 125 racks at the same time, can expand 32000 IO points.

The best carrier of embodied intelligence and a new intelligent partner for mankind. Including arm freedom; leg freedom. 18 degrees of freedom for the whole body. Purely Electric Drive.

*Pure water production capacity: 4T/H *Length of drying tunnel: 15M * Oven temperature: up to 140℃ * Heating power: three-phase 380V * Control power supply: single-phase 220V * Mechanical speed: 5-20m/min * Installed capacity: 400KW

ADTECH CNC9620/4620 2 axis Turning/Lathe Machine CNC control System for CNC lathe and turning system

Palletizing Robot solutions for Heavy box: *200kg payload *3000mm working radius *0.03mm Repeat Accuracy *Yaskawa Servo system *LNC Robot control system

【Model】TR10165B-310 【Motion type】Multi-joint type 【Rated load】165kg 【Motion radius】3100mm 【Weight】1600kg 【Number of axes】4 axes

ABB KUKA Yaskawa Fanuc etc.. industrial Robot arm 4 axis and 6 axis 6kg to 2000kg payload Within 5 years old

Similar your real girlfriend Customized body shape, face appearance and eye color options etc. Warm Body function Fluently English and Chinese speaking

Equipment Fetures: * High Speed process up to 480pcs/min. * Large payload of Delta Robot by 6kg. * Smaller design than other famous brand.

Three-wheeled Electric Forklift Introduction: 3 wheeled forklift is designed to lift standard pallet with 1200 kg load capacity and 3880 mm lifting height. Three Wheeled Forklift is an ideal facility to load/unload goods in stacking warehouses, super-market, workshops, production lines or handle goods on/off trucks, containers, etc

TRLINE-N95 production line to produce products below: Face mask for hospital N95 face mask Face mask for Coronavirus Disposable medical mask

Similar your real girlfriend Customized body shape, face appearance and eye color options etc. Warm Body function Fluently English and Chinese speaking

MIG welding robot for steel, stainless steel. Compatible with 1/2 axis Rotator table. Laser seems tracking system is available for this robot !

*Compact structure, easy for installation and maintenance *Full Servo System, speed is adjustable *PLC control, highly automatic *HMI is easy to operate *Multiple positions are equipped with detecting sensors, which are reliable to detect exceptions to reduce wastes. *Key parts and components use world famous brands for ensuring the stable performance of machine *Stable running and high efficiency

Application range: calcium carbonate crushing processing, gypsum powder processing, power plant desulfurization, non-metallic ore pulverizing, coal powder preparation, etc. Material: quartz, feldspar, calcite, talc, barite, fluorite, rare earth, marble, etc.

Manned Flying Saucer features: Maximum range: 6km. Number of passengers: 2 people (75kg/person). Advantages of flying saucers: Fully enclosed safety design, cool appearance, water take-off and landing capabilities.

AA Battery Standard Size: Diameter(D) mm 14±0.5 Height(H) mm 50±0.5 Weight(W) g 14.1±0.5 AAA Battery Standard Size: Diameter(D) mm 10.1±0.2 Height(H) mm 44.5±0.5 Weight(W) g 7.1±0.2

Spot Welding Robot TR10210A-265 features: Rated Payload: 210kg. Working range: 2658mm. Number of control axes: 6 Repeat positioning accuracy: ±0.06mm. Installation method: Formal installation. Protection level (wrist): IP65.

Entry-level mobile robot controller: SRC-880. The most cost-effective AMR controller, the best partner for differential AMR.

*Compact structure, easy for installation and maintenance *PLC control, highly automatic *HMI is easy to operate *Multiple positions are equipped with detecting sensors, which are reliable to detect exceptions to reduce wastes. *Key parts and components use world famous brands for ensuring the stable performance of machine *Stable running and high efficiency

High-performance AGI Humanoid Robot TR-Star 1: *Degrees of freedom: 55 *Maximum joint speed: 25 rad/s *Height/weight: 171 cm/63 Kg *Total machine load: 160 Kg+ *Maximum joint torque: 400 Nm *5 Fingers Hand: fully self-propelled joints / 12 independent degrees of freedom.

Sustainable Environmental Protection Concept: *The body adopts aluminum alloy skeleton *Significantly reduce the use of steel in the production process and indirectly improve the level of environmental protection *At the same time, compared with traditional diesel commercial vehicles, 50% emission reduction in the entire life cycle of pure electric mobile platforms

The handling robot is mainly suitable for large load and large-scale work occasions. Industrial Robot For Material Handling have Good general performance and Fast running speed.

AI Coffee Robot Specifications: Robot weight: 72KG Base size: 650mm in diameter Movement range: 750mm Clamping type: mechanical parallel clamping Maximum movement speed of the end of the robotic arm: 1m/s Repeat positioning accuracy: ± 0.1mm Degrees of freedom: 12+2 Clamping payload: below 3KG Input voltage: AC 100-240V Interface: RJ45x2, HDMIx1, USBx4 Programming method: PC/mobile graphical interface/Python/C++/ROS low-level interface

Best 900CC motorbike in China 2020 !

Our manufacturer's research and development, design and produce machines of gloves,balloon and condom. Mainly in balloon printing machine,production line for glove,glove half-full dipping,latex condom dipping and latex balloon dipping,glove dotting and printing machine, surgical glove out wrap/inner paper packing machine,condom packing machine and other relevant supporting equipment products.

Palletizing Robot solutions for Large board picking and placing: *200kg payload *3000mm working radius *0.03mm Repeat Accuracy *Yaskawa Servo system *LNC Robot control system

*Product advantages: fast speed, high precision *Long service life and stable performance *Strong compatibility and strong flexibility *Simple control and ease of use

Graphene Carbon Crystal Geothermal Blanket Electric Heating Carpet Geothermal Pad, Nordic Minimalist Style, With Temperature Controller, Perfect For Cold Winters, Power 500W-2000W.

3d Digital Microscope Features: *Three-dimensional viewing plane 3D mode can be switched *Light source continuous reading adjustable 0.7-4.5X optical magnification adjustable *Image storage Frame freeze, image comparison *Strong light suppression, edge enhancement *Color Independent Adjustment *White balance adjustment Automatically adjust exposure *High speed 60 frames per second Mouse operation, U disk read and write

Cobot CS66 Parameters: Six degrees of freedom, weight 20kg, load 6kg Working radius 914mm Repeat positioning accuracy ±0.03mm Maximum speed 2.6 m/s Typical power 250W Protection grade IP54

AI ontology in the intelligent era GR-1: Embodied intelligence combines artificial intelligence technology with robotic entities, giving the "brain" a controllable, perceptible, interactive, and actionable "body." GR-1 adopts a highly scalable design, which can achieve more AI model and algorithm verification, and has great potential in multiple application scenarios such as industry, rehabilitation, home, and scientific research.

Robot Applications: ——Material handling and palletizing Greater flexibility, more stable performance, and lower energy consumption; Maximum throughput with high-speed performance; Long working time; Fixed automation.

R1 Robot Features: -Used for water search and rescue, fire rescue, towing and rescue transportation. -Support remote control/local dual control mode -Support one-key return to home, out of control return to home, reverse gear -Support infrared intelligent human detection -Suitable for scenes such as the sea, reservoirs, rivers, lakes, etc.

Specifications Compatibility: Outdoor life Features: Waterproof Structures: Monocular Increase: 12X Objective Lenses (mm): 50 Eye lens (mm): 23 Prism Type: BAK4 Net weight / kg): 0.5 Listed day: 05/18/2020

Main Products: Commercial robots, teaching robots (teaching robots for universities, middle schools and elementary schools), collaborative six-axis robots, photography and video robots, beauty and body robots, milk tea robots, auto parts, elevator parts, auto parts inspection tools, precision hardware, medical equipment accessories etc.

Production Model: Fish style(KF94). Speed: 120+pc/min Rate of defect prodcution: Less than 1%. Face mask for Adult Size.

Desalination is the use of seawater desalination to produce fresh water. It is an open source incremental technology to realize the utilization of water resources. It can increase the total amount of fresh water without being affected by time, space and climate. The water quality is good and the price is gradually reasonable. It can guarantee the stable water supply such as drinking water for coastal residents and industrial boiler water supply. The process of obtaining fresh water from seawater is called desalination. The seawater desalination methods currently in use include seawater freezing, electrodialysis, distillation, and reverse osmosis. The current reverse osmosis method using reverse osmosis membranes quickly occupy the market due to its simple equipment, easy maintenance and modular equipment, and gradually replace it The distillation method has become the most widely used method.

ADTECH QS7 series AC servo drives and motors are suitable for retrofit CNC machines and Linear modules !

Electric Microscope TVN-600II_A main features: Function 1: Flashlight; Solve the problem of unclear fonts on PCBA chips Function 2: Depth of field synthesis; Solve the problem of blurred display of different depths of field Function 3: Light source shielding; Solve the problem of reflection of FPC soft board affecting observation Function 4: Ethernet port; It is convenient to transfer pictures, and there is no problem with rejecting USB disk.

Mini Drone 2021 Features: *4K dual cameras *15 minutes flying time *Maximum flying altitude 120 meters *Unit weight 0.29 kg *360 degree stunt show

UV Disinfection AI Robot is suitable for the hospitals and public venues. Good in control with the virus such as H1N* and COVID-19 by air media spreading

Smart Garden Robot Host: Leaf Blower Robot Lawn Mower Robot Snow Sweeper Robot Independently developed world's first consumer-grade smart garden snow sweeper robot

Double seats Helicopter features: 4-cylinder gasoline engine, 1800cc emissions, 120 horsepower, imported engine, lifetime warranty on the entire engine.

Engine:4 Stroke; Seats:3; Horsepower:> 300hp; Battery :12V, 36A 4 Cylinders; Color:Optional; Product Size:3100 * 1200 * 1100MM Maximum load:200kg; net weight:300kg; engine displacement:1300CC Maximum power:63KW(6000RPM); Single package size: 31X12X11 cm Single gross weight:20.000 kg; Maximum power:63KW(6000RPM) Maximum torque:11Nm(4000rpm); Lubrication system Dry oil Cooling system Water cooling double loop; Start method Electric start ECU Fuel tank capacity:35L; Oil amount :3.5L; Starter motor:380W

OEM Electric mask: Power (W): 0.5W Voltage (V): 5V Power Source: Battery, usb, Electric Materials: PP and Silicone Function: Air purifier and anti-fog smoke virus

Laser SLAM rotary lifting AMR Robot TR-SW1500: Super strong load by 1500kg, smoothly AI transport.

Digital metallographic microscope(TVN-MT4K80) is an optical inspection equipment developed for high-end manufacturing and research in the semiconductor industry, silicon wafer manufacturing industry, electronic information industry, metallurgical industry, medical testing, scientific research, etc. As a high-end metallographic microscope, users can experience its excellent image effects and a clear microscopic world at high magnification when using it. The MT40 microscope can be widely used in semiconductor research and development, manufacturing, FPD, circuit packaging, circuit substrates, materials, castings/metal/ceramic parts, and precision mold inspection. This instrument uses a high-power LED lighting lamp with two lighting forms: reflection and transmission. Bright and dark field observations, DIC observations, and polarized light observations can be performed under reflected light illumination. Bright field observations are performed under transmitted light. The stable and high-quality optical system makes the image clearer and the contrast better. The design that meets the requirements of ergonomics makes you feel comfortable and relaxed at work.

*User-friendly open tray design, bringing enjoyable dining experiences. *21 inch high-definition advertising display, expanding marketing possibilities. *Dynamic lifelike interaction, sensory communication. *CADEBOT: a multi-scenario comprehensive commercial delivery Robot.

Fixed Wing Hybrid VTOL Drone main feature: ---HD photo and video evidence collection Equipped with an airborne camera, the UAV can collect evidence of illegal acts from the air to investigate the damaged area, and cooperate with the ground police force to search for the target.

Spherical Robot Dynamic inspection: The spherical robot moves smoothly and flexibly, is easy to control, and can be used on a variety of road surfaces; the closed spherical shell has strong self-protection capabilities and is anti-overturning. The robot uses advanced control algorithms to enable it to move flexibly in a variety of scenarios.

Smart AMR Forklift: The intelligent forklift series products are equipped with SRC core controller and use laser SLAM navigation, no reflector, the whole vehicle is equipped with 360° safety protection, which can meet Loading and unloading, sorting, handling, high shelf stacking, cage stacking, pallet stacking, etc. Scenario requirements, this series of products have rich models and a wide range of loads, such as pallets, materials. The handling of cages and racks provides a powerful solution.

A smart and cool two-wheeled Robot, and also an open development platform.

Metal processing industry: blanking on punching machines, CNC loading and unloading, workpiece grinding, deburring; Electronic products industry: assembly, IC chip testing and handling, spot welding, PCBA soldering, glue application, screwing, plug-in, workpiece polishing; Automobile and motorcycle parts industry: handling, gluing, spot welding; LCD/LED and glass industry: handling of glass plates, assembly of LCM modules, handling of silicon wafers and display screens; Laser industry: spot welding, cutting; Home appliance industry: assembly, handling and screwing of home appliance products; Research areas: student teaching, school research and development.

Firefighting Robot TR-M4DA: The high-temperature-resistant firefighting robot adopts a number of high-temperature-resistant patented technologies, giving the robot the ability to continuously work in a high-temperature environment of 1000°C for more than 30 minutes. It can replace fire fighters who go deep into dangerous high-temperature fires for long periods of time to conduct fire reconnaissance and fire-fighting work. It is extremely The earth has expanded the combat scope and capabilities of fire rescue personnel.

Robot Mechanical Parameters: Overall dimension: 1150(L) x 730(W) x 1138(H) Net weight: 280kg Electrical parameters: Battery voltage: 48V; Battery capacity: 130Ah Working hours for a single endurance: 6-8h Battery type: Lithium battery Performance Parameter: Working speed: Max: 1.3m/s, suggestion: 0.6m/s Cleaning efficiency: 2300㎡/h (typ1288) Cleaning width: 552mm Brush type: Double rolling brush Tank volume: 120L (internal circulation) Working noise: <76dBA

Equipment Fetures: * High Speed process up to 600pcs/min. * Large payload of Delta Robot by 7kg. * Japanese Panasonic Servo Motors. * Smaller design than other famous brand.

Working Radius: 400mm Payload: 1.5kg Repeat accuracy: 0.02mm Drag teaching system Anti-collision function

A professional design, manufacture all kinds of gloves equipment production enterprise, its excellent product quality and first-class service to win the customer high praise and recognition. Brings together various excellent equipment research and development personnel and chemical formula of talent, and with a number of well-known domestic and foreign manufacturers, companies, universities and research institutions established long-term strategic partnership, committed to the mechanical equipment frontier technology research and development of new products.

TR600B four axis SCARA industrial robot The robot is a multi-joint four-axis robot with complete independent property rights. It adopts a high-performance controller to control the robot to achieve high-speed point motion, spatial linear interpolation motion, spatial arc interpolation and other functions. It is suitable for transportation, Various industrial occasions such as loading and unloading, spot welding, gluing, etc.

Slurry Balance TBM: Mud is used as the main medium to balance the ground pressure on the tunnel excavation surface, and slag is discharged through the mud conveying system. The excavation diameter covers 2.7 meters to 17 meters.

Robot Applications: ——Material handling and palletizing Greater flexibility, more stable performance, and lower energy consumption; Maximum throughput with high-speed performance; Long working time; Fixed automation.

Atomic energy batteries can generate electricity stably and autonomously for 50 years without charging or maintenance. They have entered the pilot stage and will be put into mass production on the market. Betavolt atomic energy batteries can meet the needs of long-lasting power supply in multiple scenarios such as aerospace, AI equipment, medical equipment, MEMS systems, advanced sensors, small drones and micro robots. This new energy innovation will help China gain a leading edge in the new round of AI technological revolution.

ADT-8960 is 6 axis PCI control card, it can support random 2,3,4,6 axes linear interpolation.And adopt advance technology, the frequency error is less than 0.1%.

High Speed Round Printing Machine applications: For Barrel, Plastic cup, and round shape items. Over 1000pc/minute.

Industrial Delta Spider Robot: 400mm-1200mm working diameter 1-3kg rated payload KEBA teach pendant

EDU Robot Applications: Commercial robots, teaching robots (teaching robots for universities, middle schools and elementary schools), collaborative six-axis robots, photographic camera robots, beauty and body robots, milk tea robots, auto parts, elevator parts, auto parts inspection tools, precision hardware, medical equipment accessories, etc.

CNC Machine of Main Parts by: *The body weight is 855kg. *Mitsubishi M80 system. *11KW10000 rpm. *24 arm magazines. *X35MM YZ45MM *Japan THK roller guide Z axis 6 sliders

It mainly includes two parts: intelligent mobile platform and automatic killing system. The automatic killing system is under the core control system of the robot. You can use voice to control the killing power, killing range, killing path, killing time, etc.

Equipped with an L4 water surface automatic driving system, manual/automatic driving can be switched independently, bringing a new tour experience. It is suitable for water surface sightseeing, transportation connection, research experience, water afternoon tea and other scenarios, and promotes the rapid realization of water tourism and water transportation. Digitization and intelligence.

laser cleaning machine TR-CL2000 features: 1. High-power fiber laser laser cleaning machine 2. Non-contact cleaning, no damage to the parts matrix 3. Precise cleaning, can achieve precise location, precise size, selective cleaning 4. The operation is simple, just power on, and it can be hand-held or cooperated with the manipulator to realize automatic cleaning. 5. The cleaning effect is very high and saves time. 6. The laser cleaning system is stable and requires almost no maintenance.

Similar your real girlfriend Customized body shape, face appearance and eye color options etc. Warm Body function Fluently English and Chinese speaking

【Model】TR1005A-099 【Action type】Multi-joint type 【Rated load】5kg 【Motion radius】990mm 【Weight】55kg 【Number of axes】6 axes

Heavy-duty Unmanned Tractor model T300-H features: *EPS electric power steering, flexible and precise steering *Laser SLAM + blind spot radar navigation *Towing capacity up to 33Kn, smooth and reliable operation *Quick-release design for easy inspection and maintenance *High-power servo motor drive for high parking accuracy *All-weather operation, both indoors and outdoors.

Controller Battery: 3.7V 300mA Motor: 1806 brushless motor Item name: SJRC F11 RC brushless drone Charging time: About 3.5h Flight time: About 25 mins GPS/GLONASS double mode: YES 5G Wifi image transmission distance: 400-500m (Free interference and no occlusion) Camera: 90deg adjustable angle by remote controller

Electric Stand up Forklift Introduction: Stand up electric forklift is designed to lift standard pallet with 500kg load capacity and 2000mm lifting height. Electric Forklift is an ideal facility to load/unload goods in stacking warehouses, super-market, workshops, production lines or handle goods on/off trucks, containers, etc

Power phase number: single phase Rated power: 20W Moisture-proof way: open Cooling method: oil-immersed air-cooled Cooling form: liquid/oil immersed Frequency characteristics: low frequency Brand: OEM Winding form: double winding Core form: shell/core shape

Unmanned Forklift TR-TF2000A: Unmanned counterbalanced forklift is based on a positioning and navigation system that integrates multiple sensors such as multi-line lidar, RTK, and inertial navigation. It can provide an overall solution for unmanned cargo forking, multi-machine scheduling, and logistics automation, and can identify and locate pallets, cargo, production lines, etc. in complex scenarios, thereby performing precise forking and handling operations.

The system of latex balloon dipping machine realized communication controlled by humanity-machine interface. They raise the digitized level of the system having it steady. Industry level modularization design, simple humanity-machine dialog and main speed and every section temperature can be shown in the screen.

The unmanned forklift (AGV) adopts Japanese AGV technology. After years of localization exploration and testing, it now has excellent practicality and rich applicability. The characteristics of in-situ rotation, human-computer interaction friendliness, easy expansion, and easy integration have become the technical representatives of Uwangte AGV. The AGV scheduling system has the function of route control, route avoidance and automatic calls and task scheduling.

TRL series robot stacking unmanned forklift application scenarios: factories, warehousing, workshops, logistics, etc. Mainly used for pile height.

1. Aluminium alloy structure is adopted, which is beautiful and firm without rust. 2. Computer PLC programming control, high stability, low failure rate and low noise. 3. Adopt imported servo motor, stepper motor drive, high precision. 4. Photoelectric detection of raw materials to avoid mistakes and reduce waste. 5. The machine adopts heavy-duty casters and cushion foot cups to move and fix, which is convenient and fast to move without shaking or hurting the floor. 6. The model is equipped with a new advanced conveyor belt, which automatically collects products with high accuracy, and only needs to be sorted and packed.

Product Applications: * Industrial Robots vision system * Industrial machines vision system * Defect Products Inspection * Porduct Position Controls * QC Checking for micro products

Power: 5W Range: Over 2000m Battery type: 18650*2 lithium battery Dimension: Length 21.5cm * Diameter 4cm.

ADTECH 12 Axis CNC Spring Maker Machine Controller is designed for building up the no CAM type spring machines.

Adult Diaper machine: Customized specification; 3-shaft drive/Full servo, timing belt and flat belt are imported products, and all the key parts use imported bearings. Germany BST automatic web guide system (optional).

The security patrol robot has four core technologies with independent intellectual property rights, creating a smart new security model of human-machine collaboration, and helping the police to develop through science and technology. At present, patrol robots have very mature applications in airports, stations, supermarkets, pedestrian streets and other scenarios.

*Equipped with visual positioning, depth vision camera, lidar *Precise positioning and navigation of walking routes, autonomous planning *Multi-machine collaboration and orderly distribution

TR-M2 Pipe Network Inspection Robot: Quickly locate internal structural defects of drainage pipes. Meet the inspection needs of conventional pipelines and complex pipelines. Rapid testing generates test reports.

Tandem Press Line Description: 1. The use of frequency conversion speed regulation can flexibly match the production speed. 2. Two optional modes: continuous conveying mode and step conveying mode. 3. The production line can be stopped through the conveyor line, which is convenient for customers to use. 4. The belt is made of wear-resistant material.

Main functions: Press EVA, solar cells, tempered glass, and backing film (materials such as TPT) into a rigid unit under high-temperature vacuum conditions.

MV800 Motorcycle is looks like Harley style, comfortable seat with strong engine with 800cc, V-cylinders. feel pleasure with your holiday traveling in a great weather.

Mobile Robot Platform parameters: Curb weight: 70KG Rated load: 85KG Geometric size: 974.16*782.02*364 (mm) The fastest speed: 2m/s Obstacle surmounting ability: 160mm Motor parameters: 4*400W brushless servo motor Communication interface: CAN/232 serial port Climbing angle: <30° Turning radius: 360° in place Battery: 48V30AH lithium battery

Purpose and characteristic: This sterilization machine can quickly kill 99% bacteria and viruses, including: influenza, hepatitis virus, e. coli, golden yellow staphylococcus aureus, bacillus subtilis variant spore and various black mildew source body, the allergy source, to the daily life of people to provide a safe environment, especially suitable for tableware, food, cosmetics, Chinese herb, and public goods, children's toys and other items such as surface fast disinfection and deodorization in addition to taste

Vertical Parking Garage advantages: ◇ It saves space and can be doubled by occupying only 2 parking spaces. It does not require a large area to build a three-dimensional parking lot; ◇ Smooth operation, no vibration and noise; fast operation speed, short access time; ◇ Standardized mechanism design, smooth operation, safe and reliable; ◇ Equipped with safety protection devices and emergency stop devices to ensure safe operation of access vehicles; ◇ Equipped with photoelectric detection, program control, automatic access vehicle, and can be managed unattended; ◇ One-time investment, long-term benefits.

Easy to operate: Force-free teching effectively reduces debagging time and learning cost, friendly interface for much easier to use. Modularity: All-in-one module of reducer,motor,encoderand drive,which is convenient for quick disassembly. Quick deployment: 5kg in rated load with 18.5kg in weight.Light-weight installation and flexible deployment.

Semi Automatic Taping Machine Applications: The trend of industrial automation requires SMT operations in the electronics industry, inductors, transformers, connectors, crystal oscillators, semiconductors, metal stamping iron sheets, various JACKs, ICs, USBs, energy inducers, antennas/reeds, switches, electric keys, switches, chargers, etc. The packaging methods of SMD patch electronic parts such as battery holders are all transferred to the carrier tape packaging. SMD semi-automatic packaging machines and automatic packaging machines are equipment that handle packaging operations well.

The world's lightest active 20kg waist-assisted exoskeleton robot product is a small device with great assistance, high cost performance, high flexibility, and is easy and comfortable to wear. Currently, only prototypes are available for trial use, but it has attracted enthusiastic attention from overseas customers and has received orders. It can be widely used in logistics, industry, and nursing fields.

Industrial robot manufacturer in China with cheap price ADTECH FR5215 system 5500mm arm length 4 axis hoisting scara robot with AVS vision system. ADTECH is professional in 4-axis Scara robot R&D, producing and service. For reduce products people cost. More and more robot is used on production line.ADTECH scara robot can replace NACHI,TOSHIBA,etc. Japan brand, It is application for PCBA assembly,screwing loading,packing,etc electrical field.

The six-color bending offset printing machine adopts a reasonable structure and high-quality accessories to ensure the machine is durable, practical, high-quality printing, high production efficiency, and easy to operate. This machine is letterpress printing, mainly suitable for surface printing of cups and bowls

1, Conditions of use:380V/3phase/50HZ; 2, Materials used:PP meltblown special material;melt fat 1500 3, Product specifications:L=420mm, δ=0.008~0.1mm 4, Extrusion output:25~50Kg/H varies according to material,thickness and process.

Lower Exoskeleton Robot Main functions: *Servo power unit *Three force impedance control technology *Force control integrated drive unit *Integrated TBG (Twist Belt Gear) *Deceleration system

Similar your real girlfriend Customized body shape, face appearance and eye color options etc. Warm Body function Fluently English and Chinese speaking

Industrial Delta Spider Robot: 400mm-1200mm working diameter 1-3kg rated payload KEBA teach pendant

M820 series product feature: *50% reduction in volume and wiring time *30% energy savings *3.2kHz response speed

Abdominal Toning Belt features: * Smart phone controls * EMS IC chip * 8 difference mode * 50 levels * Auto stop by 25 minutes * One button operation

Physical safety system: Far-field protection: ØFar-field 360° 150m instant mapping, real-time positioning, navigation ability Near-field Protection: ØNear-field 360° safety protection: Ø6m 360° ToF camera day and night obstacle avoidance Ø6m ultrasonic fusion human monitoring, glass anti-collision ØBelow 5cm protection of 3m small dot pitch infrared laser array ØAnti-fall and mechanical edge contact

Laser SLAM Smart AMR Robot forklift type: *2 Ton stacking payload; *Maximum Lifting Height reach to 3000mm; *Compact and Flexible.

FPC Machine Model: TR-CA5252. Conventional FPC board/new energy FPC board, cover film, EMI, whole sheet to sheet, or sheet to roll.

Features Easy operation Best configuration with high performance Long arm length suitable for wide places Max payload 10kgs Fast speed with 0.43S cycle time High precision up to ±0.015mm