Call Us Now

TEL: +86-4000988557;

Teams: gfreex@hotmail.com;

WeChat: Troysupply_com;

QQ ID: 8936906.

Item No.:

TR501DTPayment:

FOBProduct origin:

ChinaShipping port:

ShenZhen portsLead Time:

20 daysDual Workstation Soldering Machine(TR501DT)

Description

• 6 axis (X,2Y,Z,R and 1 soldering wire feeding system) with equipment travel to 500mm.

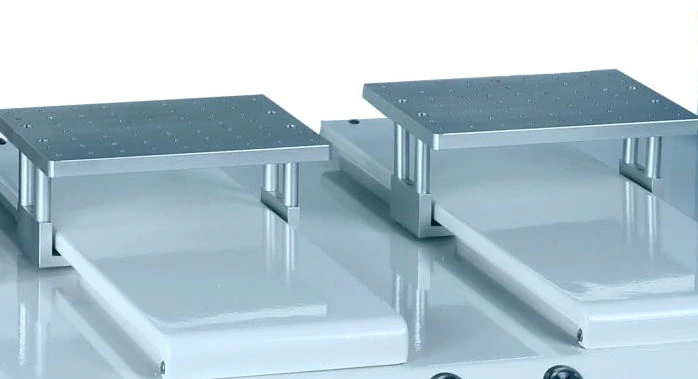

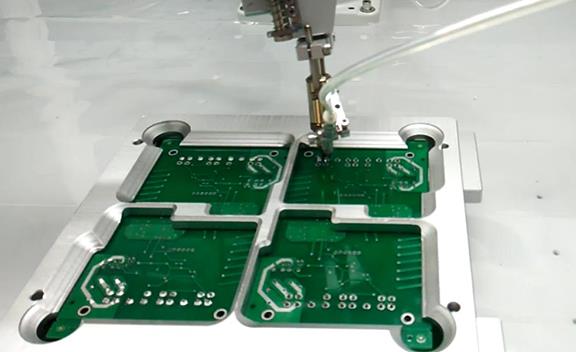

• 2 workstations allow soldering and disassembly to be carried out step by step, the soldering head never stops, which improved efficency greatly.

• The double stations can also be operated at the same time, one welding and the other is ready for the welding, switching seamlessly.

• Self-developed software runs under windows 7 English OS for easy operation and training.

• Real digitalized software with 2.4G wireless remote control, mouse and keyboard.

• 12- inch full touch LCD screen

• Own brand 400W or 600W (optional) high frequency heating system with rapid heat recovery.

• Soldering tip can be easily changed into the low cost one.

• Break-tin automatic solder wire feeder can reduce tin brust that cuases flux remaining on PCB when soldering under high temperature to improve the soldering quality.

• Comply with CE and RoHs complaint.

Features

Specifications

|

Model |

TR501DT |

|

Axis |

6-axis(X/2Y/Z/R/wire feeder) |

|

Equipment travel(X/Y/Z/R) |

500*350*350*90mm*330° |

|

Max running speed (X/Y/Z/R) |

X/Y/Z:0-600mm/s R:180°/s |

|

Repeat positioning accuracy |

±0.02mm |

|

Load |

10KGS |

|

Program recording capability |

Unlimited |

|

Display mode |

12 ” LCD touch screen |

|

System platform |

Windows 7 OS professional |

|

Programming method |

Touch Screen + Wireless Remote |

|

Motion system |

Stepper motor |

|

Temperature Range |

180℃~450℃ |

|

Soldering wire feeding system |

Independent drive and Stepper motor |

|

Soldering wire specification |

0.3-1.6mm ( can be customized) |

|

Min soldering wire feeding length |

0.1mm |

|

Power supply |

Single phase 220/110V AC 50/60 HZ |

|

Air pressure |

0.4-0.8MPa |

|

Work environment |

0 – 40 ℃, Ralative humidity:20%-90% |

|

Machine Size(mm) |

W750*W594*H854mm |

|

Weight |

110Kgs |

|

|

|

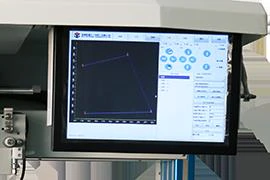

Smart Operation System

Main User Interface

TROY soldering robot operation system is based on windows 7 OS and uses PC for controling, which is fast and stable.

The most advantage is the user interface is very simple and can improve the efficiency of production effectively; Running speed of every point can be set individually.

The machine will automatically calculate the set runtime to judge if it needs necessary adjustment to ensure a smooth running and prolong the life of the machine!

Authority Management

TROY smart soldering operation system allows different authority management,which is suitable for different limited manage.

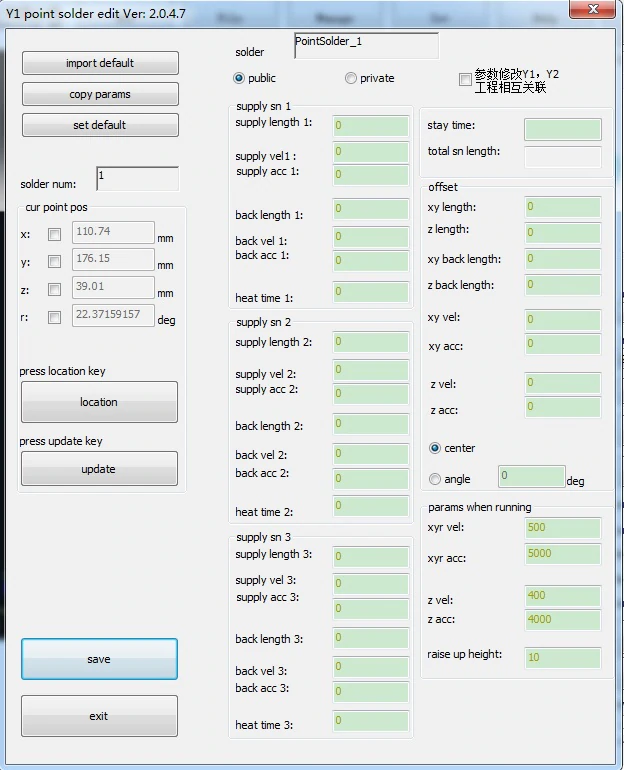

Spot Soldering Setting

Ternary automatic soldering feeding form and with tin pre-heating

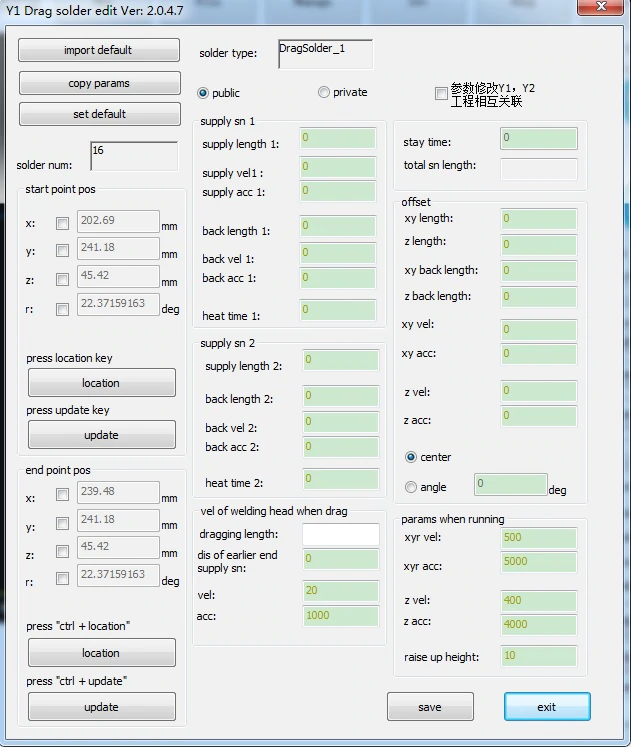

Drag Soldering Setting

People may say drag soldering or line soldering, its suitable for some standard equal or duplicated soldering spot.

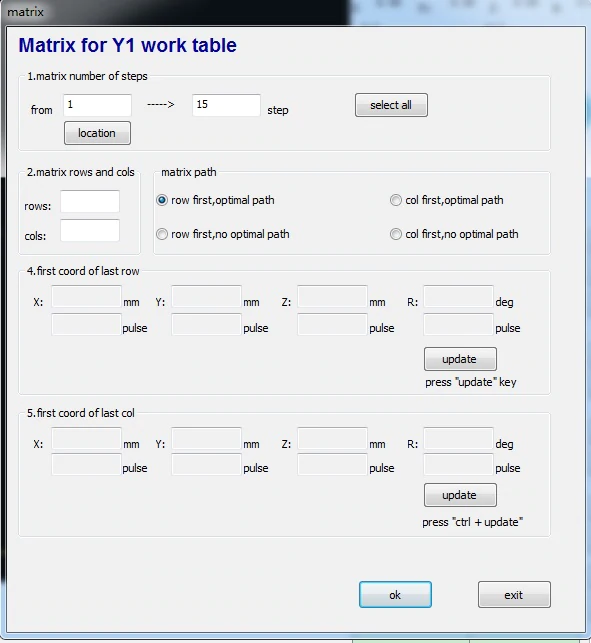

Matrix Soldering Setting

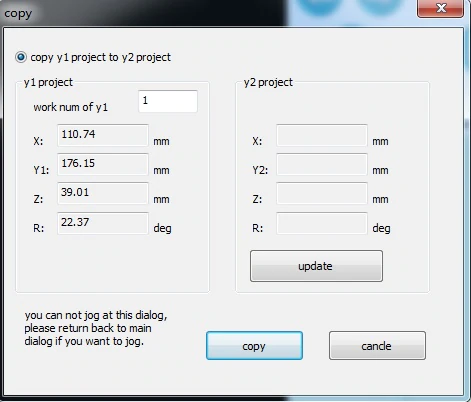

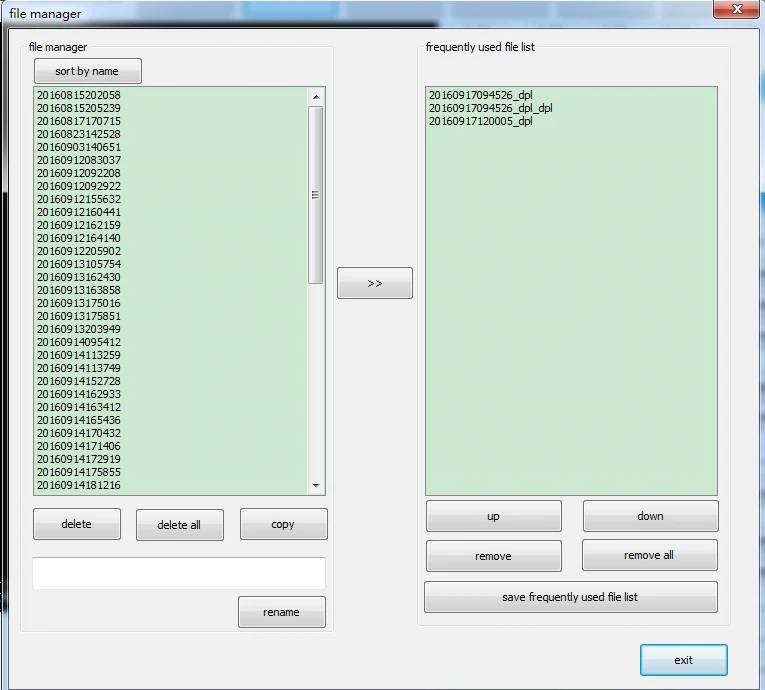

Pareameter Duplicate

Smart soldering OS allows data duplicate to different PC or different work stations.

Parameter File

Each parameter file for different products

Configuration

Interaction Touch Screen

12-inch HD touch screen main operation interface, simply tapping to operate this soldering robot and Monitoring all the moving tracks to make soldering machine working smoothly.

High frequency induction heating system with touch screen control panel, simply tap for temperature setting. Innovative solder temperature algorithm enable temperature recover rapidly to make sure soldering robot create perfect soldering.

Free to design unique soldering tip for each clients. Compared to other soldering tips, scientific designed tips will help to save 1/5 to 1/4 solder tin, which is best used for different special research or develop purpose.

All of the control elements, including industrial PC,driver of stepper motor for X Y Z R axis,motion controller,protection parts,air cylinder controler, power controller etc. installed firmly on this base metal plate.

Its the body of the automatic soldering robot.

The wireless remote control accesses most control operation from industrial PCs, which assists you more easier to program on welding robots.

Operation Buttons

START STOP RESET Emergency Stop

Applications:

For those simple products but with small size, soldering robot added standard fixture to make sure the satisfied soldering effect.

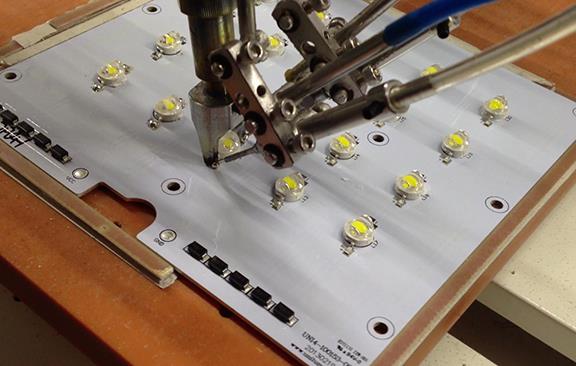

LED illumination industrial is an early modernization equipped with this automatic soldering robot.

The automatic welding robot TR501DT runs stably with different Pcb mounting intensive components, welding in small gaps quickly without damage.

For lead-free soldering of large-scale industrial wire soldering, a more powerful solder joint can be constructed.

This model of TR501DT soldering robot can be used for different electronic soldering, creating round and perfect solder joints for high quality USB flash memory. We offer OEM tips for different products.

The most precision demand of military and aviation products requests the best soldering process, TR501DT soldering robot services many of this kind of c

Online service

Online service 4000988557

4000988557 sales1@troysupply.com

sales1@troysupply.com sales2@troysupply.com

sales2@troysupply.com Richard Liu

Richard Liu TROY

TROY 8936906

8936906 Troysupply_com

Troysupply_com