Call Us Now

TEL: +86-4000988557;

Teams: gfreex@hotmail.com;

WeChat: Troysupply_com;

QQ ID: 8936906.

To prevent and control the epidemic(COVID-19), masks are a necessity

How to increase the production capacity of masks in a short time?

Chinese Airlines

Use the technology of manufacturing Jet-10 and Jet-20 large aircraft

Developed a fully automatic mask production machine

24 machines are expected to have a daily production capacity of 3 million

These masks with "aviation temperament"

And fully automatic production equipment

What does it look like? face mask machine

The reporter will take you to find out!

"Aviation temperament" mask machine

Fully automatic 24 hours, 100 pcs per minute

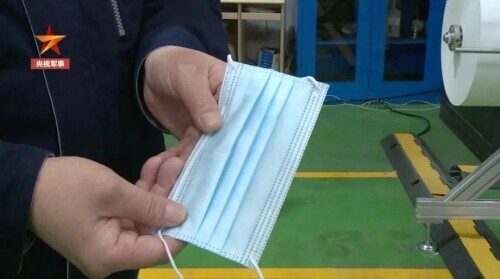

The mask produced by the automatic mask production line is composed of three layers of cloth. The outermost layer is a non-woven cloth, melt blown fabric which can inhibit bacteria. The middle layer is the most critical melt blown cloth, which is mainly used to isolate viruses.

So, how does the fully automatic mask production machine work?

First, from the part of the machine shown in the figure below, pull three layers of raw materials forward;

Then, the three-layer cloth is pleated and sliced by the instrument;

Then to the distributor, the distributor distributes the cut masks to the two welding machines on both sides;

Each welding machine welds the ear straps at a speed of 50 pieces per minute, and the mask is made.

The key to this mask machine is "fully automatic" and can work continuously for 24 hours. One machine produces 100 pieces per minute, and one worker can operate multiple machines.

Compared with traditional mask machines, fully automatic mask machines have the advantages of fewer people, high efficiency and strong stability.

At present, 24 such fully automatic mask machines have been included in the production plan, and 4 have been completed and delivered to the mask factories in urgent need in various regions.

The director of the China Academy of Aviation Manufacturing Technology and the commander-in-chief of the fully automatic mask machine development project introduced: “These 24 mask machines are expected to be completed by the end of March. By then, the production capacity of 3 million masks per day will be achieved, and the daily supply will be realized in the short term. The ability to produce more than one million."

"Aviation technology" to help

3 days to complete drawings, 16 days to make samples

The successful roll-off of the fully automatic mask machine has alleviated the urgent need for manpower shortage in traditional mask factories.

In fact, at the beginning of the equipment development, researchers did not even know what the captain of the mask was.

For them who build airplanes, the development of a mask production machine is unfamiliar. China Aviation Manufacturing Technology Research Institute quickly mobilized 7 subordinate units to give full play to their respective technical advantages. More than 600 people form a design and R&D team, working 24 hours a day.

They used digital technology in the aviation manufacturing field to complete the drawing design of the mask production machine within 3 days, and the first prototype was successfully developed 16 days later.

The person in charge of the project said: “This digital design and production technology helps to save time when developing the J-10, J-20 and other aircraft because it can be simulated before being put into physical manufacturing, reducing unnecessary occurrences in the manufacturing process. The mistake of this time. It is the pride of aviation people to provide medical workers and people across the country with protective equipment support during the epidemic!"

Online service

Online service 4000988557

4000988557 sales1@troysupply.com

sales1@troysupply.com sales2@troysupply.com

sales2@troysupply.com Richard Liu

Richard Liu TROY

TROY 8936906

8936906 Troysupply_com

Troysupply_com