Call Us Now

TEL: +86-4000988557;

Teams: gfreex@hotmail.com;

WeChat: Troysupply_com;

QQ ID: 8936906.

In recent years, mobile robots used for product sorting and handling have been widely used in manufacturing, logistics and other scenarios, and the deployment effect has been continuously improved, attracting more and more attention. Focusing on the front line, the application of AGV (Automated Guided Vehicle) is becoming mature, but with the continuous improvement of people's requirements for robot intelligence, AMR (Autonomous Mobile Robot) has gradually entered the public eye. And by virtue of its flexibility, easy operation, and easy deployment, it has gained market recognition. The new crown pneumonia epidemic has also deepened people's thinking about "unmanned" and accelerated the pace of landing and promotion of such mobile robots.

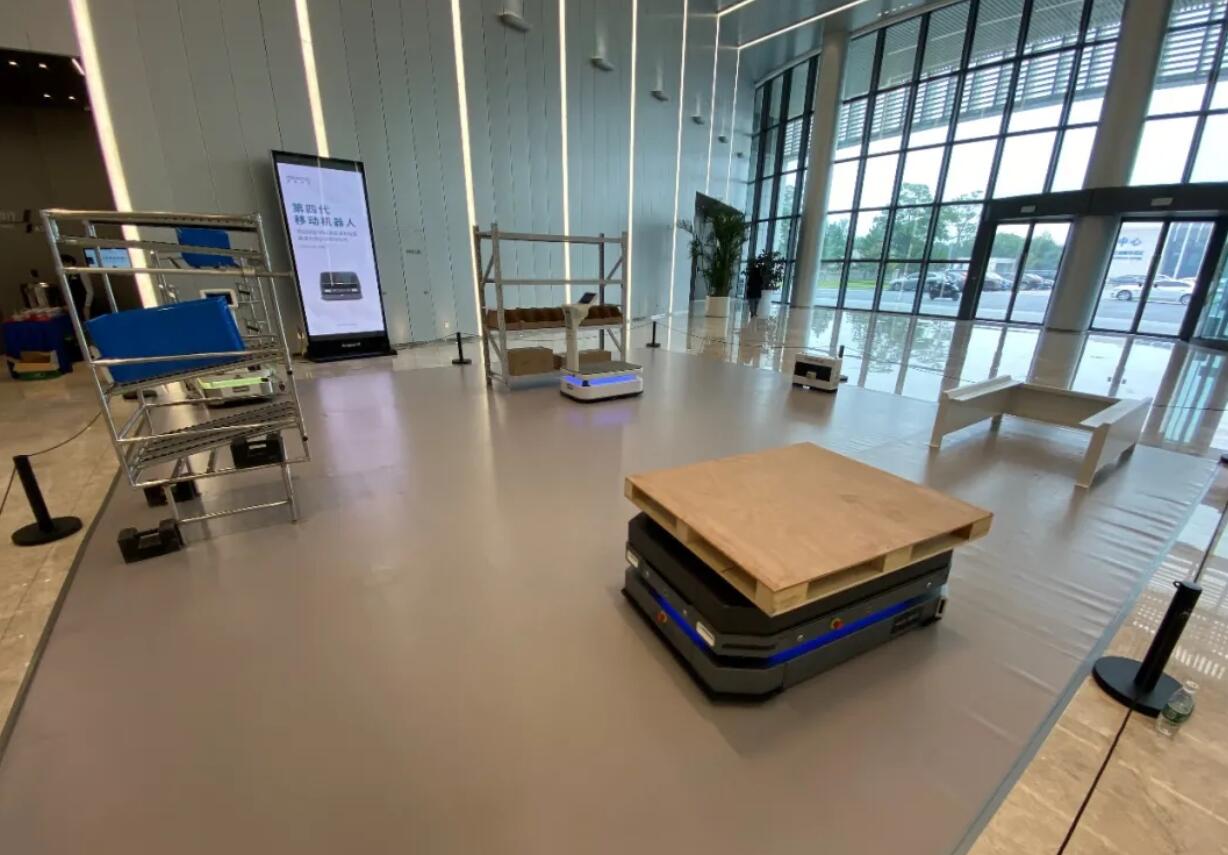

On August 26, 2020, Beijing held a new Max product launch conference. And just in April this year, in addition to the two products of ForwardX Max 600 and ForwardX Max 200 jack-up version placed in the corner of the stage, it is worth noting that, Although the demonstration area is not large, products such as ForwardX Max 600 jack-up version, ForwardX Max 200 jack-up version, ForwardX Flex RFID and other products can still "perform their duties" in it. Although occasionally "meet on a narrow road", the robot will always Be able to take avoidance measures autonomously and then continue to perform tasks. Before the conference, a lot of audience gathered around the demonstration area. People watched and asked questions from time to time. As people’s curiosity and enthusiasm for the product continued to rise, the staff on the side played the role of workers on the spot, and human-computer collaboration simulated the product distribution. Picking and handling operations attract people to take pictures and record.

It is reported that the ForwardX Max 600 has a maximum load of 600 kg, has 360-degree low obstacle avoidance and 99.9% safety. It can be widely used in manufacturing production line materials, tailings, and finished products transportation, and can seamlessly connect logistics Warehousing and transportation of the industry, multi-scene reuse, flexible and intelligent, stable and reliable.

Launched RaaS model, reducing cost and increasing efficiency by more than 30%

RaaS stands for Robot as a Service, and its promotion in the manufacturing sector is relatively deep. In recent years, with the rapid development of warehousing and logistics, the RaaS model has been further popularized and is also well-known by more people.

ForwardX Max 200 has increasingly stable performance and high ROI. In the third quarter of 2019, ForwardX Max 200 took the step of commercialization. Now it has passed the first-phase project acceptance of many well-known companies, and gradually carried out a number of second and third-phase project replication. According to reports, in response to the pain points of the SMT workshop of the production department of TCL Huizhou Movement Factory, and the collaboration of Huawei, China Mobile and other companies, the 5G version of V-AMR was quickly launched, which realized efficient mixed traffic of people and vehicles, automatic obstacle avoidance, and automatic driving across floors in the factory workshop. , The formation of "one-key transportation" full-process closed-loop management, reducing production line costs by more than 30%.

In addition, based on the business mid-office system developed by AMR robots that includes the process engine, task center, and intelligent scheduling functions, and the delivery platform system that includes deployment tools, secondary development and other modules for delivery, the ForwardX Max 200 solution can support edge Multiple logistics, manufacturing, and retail operation modes such as sorting side sorting, sorting first and sorting later, whole order picking, intelligent grouping, dynamic partitioning, timed tasks, instant tasks, etc., to achieve 80% function reuse, only 20% or more Less custom development.

Under the support of the above system, the ForwardX Max 200 RaaS model hopes to allow small and medium customers to enjoy the high output, high flexibility and high intelligence of ForwardX Max 200 by investing less in leasing service fees.

Experts explain AGV and AMR in detail

When it comes to mobile robots, many people think of AGVs. Compared with them, what are the specific advantages of AMR?

"From the perspective of concept definition, AGV is an automatic guided transport vehicle, which generally refers to a transport vehicle that realizes unmanned driving through positioning and navigation technologies. AMR refers to an autonomous mobile robot. Compared with AGV, AMR is related to artificial intelligence and automatic navigation. And other technologies are more closely integrated, and they have strong computing capabilities. They can collect and analyze the surrounding environment and data through sensors to achieve a certain degree of autonomous decision-making capabilities.

In view of the difference between the two, "From the actual application point of view, compared with AGV, the advantages of AMR are mainly reflected in the high degree of intelligence, deployment cost savings, and higher application flexibility. First, AGVs generally use panoramic maps of the scene collected in advance. Based on the way of planning the route of the map model, the AGV fully complies with the programming instructions of the control system during the movement, runs according to the preset fixed route, and cannot automatically detour when encountering obstacles. AMR can import maps and install GPS , Sensors, embedded path planning algorithms and other methods, real-time detection of the surrounding environment, and autonomously perform optimal path planning. Second, from the perspective of deployment costs, AMR eliminates the need for traditional AGVs to install wires, magnetic strips, QR codes and other equipment The process of reducing equipment procurement and plant infrastructure transformation costs. Third, AMR is more adapted to the requirements of modern manufacturing for agile manufacturing. When the manufacturing plant production unit, supply unit, storage unit, etc. change, AMR can quickly use the new map The construction and redeployment breaks the application bottleneck of traditional AGV infrastructure limitations and fixed lines."

In 2019, my country added 33,000 mobile robots (AGV/AMR) of various types, the market size reached 6.1 billion yuan, and the market growth rate remained above 40%. Affected by the new crown pneumonia epidemic, my country's traditional manufacturing industry generally faces the pressure of enterprises to resume production and work. The above-mentioned mobile robots rely on the advantages of "unmanned, automated, and flexible", which can alleviate the adverse impact of the shortage of employees to a certain extent. Especially in the post-COVID-19 era of my country's new crown pneumonia, the traditional manufacturing industry that relies heavily on manual labor will more clearly recognize the importance and urgency of carrying out intelligent transformation. Therefore, a new round of intelligent transformation of the domestic manufacturing industry will also drive the application and deployment of such mobile robots in various industries.

Online service

Online service 4000988557

4000988557 sales1@troysupply.com

sales1@troysupply.com sales2@troysupply.com

sales2@troysupply.com Richard Liu

Richard Liu TROY

TROY 8936906

8936906 Troysupply_com

Troysupply_com