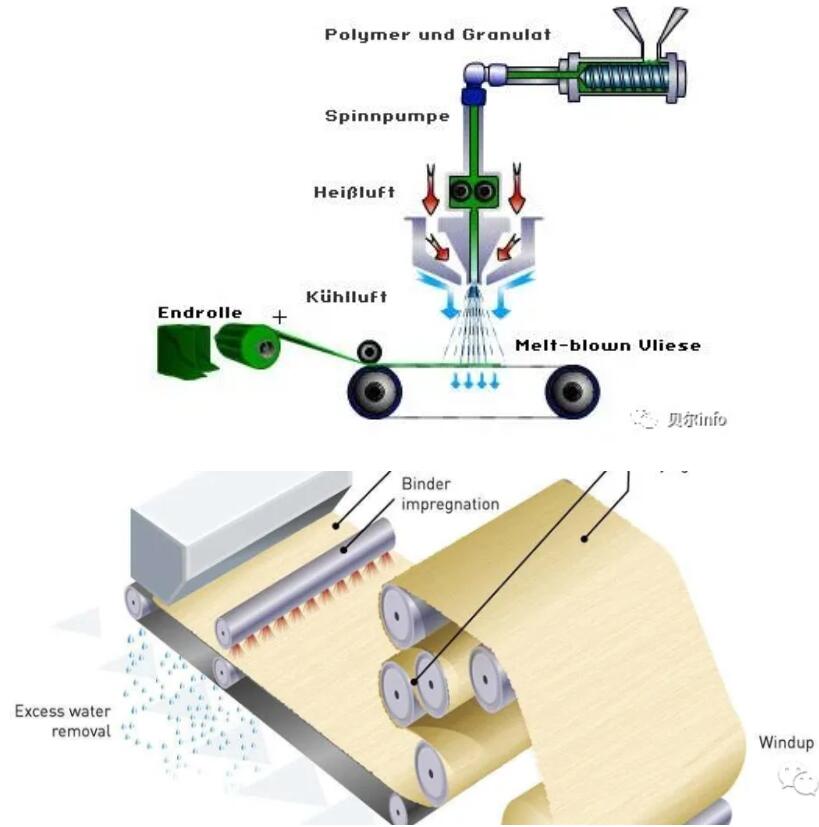

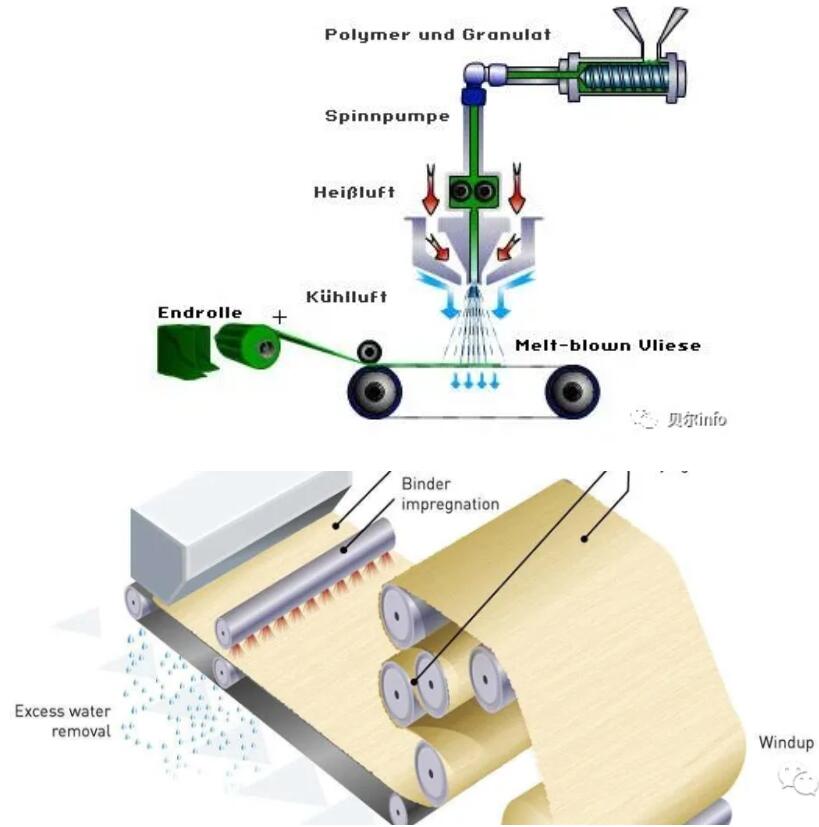

Melt blown cloth is to use high-speed hot air flow to draw the thin stream of polymer melt extruded from the nozzle hole of the die, thereby forming ultra-fine fibers and collecting them on the mesh curtain or roller, and at the same time bonding themselves to become Melt-blown non-woven fabric.

The meltblown fabric widths of regular manufacturers are generally 1600mm, 2400mm, 3200mm, and the extruder diameters are usually 90mm, 105mm, 135mm. However, after the epidemic began, the small computers (that is, the ones used by the Yangzhong family workshop) were small in width, usually only tens of centimeters, and the screw diameters were mostly 45mm, 50mm, and 65mm.

This

kind of machine has low output and low quality, but the cost is cheap,

and the delivery time is fast. The price before the epidemic was only

20,000 to 20,000, but now it has risen to 200,000, but it is still much

cheaper than the extruder of regular manufacturers. At present, the melt blown fabric machine from the mainstream 1600 regular manufacturers in the market sells for more than 6 million yuan, and the delivery time is more than 2 months.

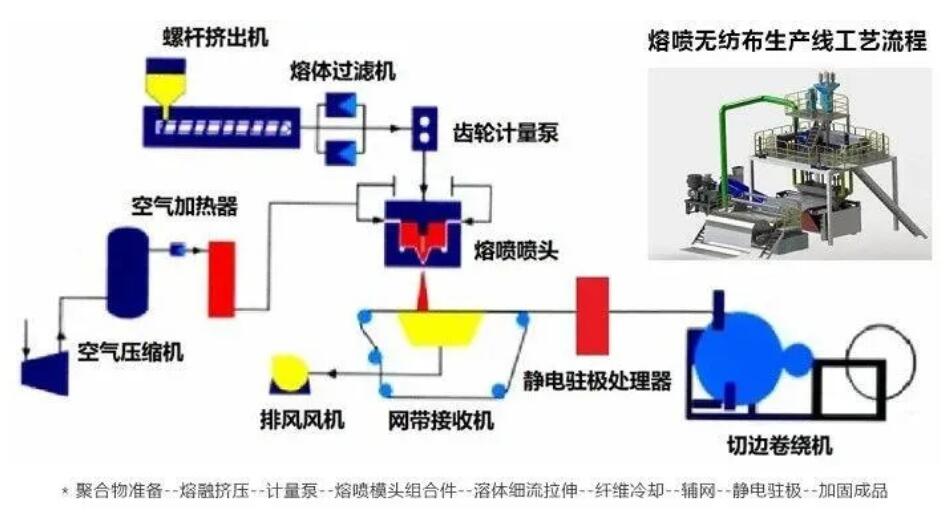

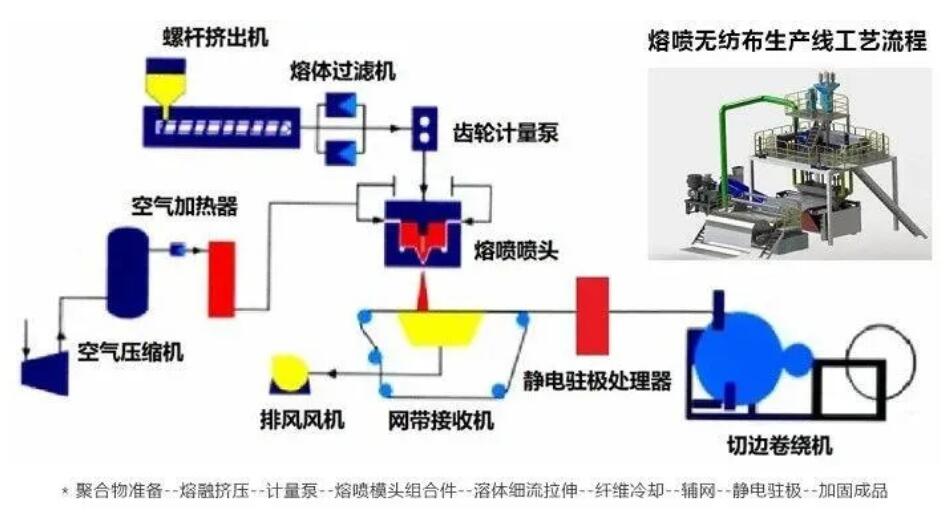

The production process of melt blown cloth is mainly as follows:

1. Melt preparation

2. Filter

3. Measurement

4. The melt is extruded from the orifice

5. Melt trickle drawing and cooling

6. into the net

Overview and principle of melt blown cloth equipment

Melt-blowing is a method that relies on high-temperature, high-speed airflow to blow the polymer melt so that it can be quickly stretched to prepare fibers.

After the polymer chips are heated and pressurized by a screw extruder into a molten state, they reach the spinneret hole at the front end of the nozzle through the melt distribution channel, and are then stretched by two convergent high-speed and high-temperature airflows to make them thin .

The thinned fiber is cooled and solidified on the mesh device to form a melt-blown non-woven fabric.

Components of melt blown cloth equipment

Key equipment such as melt blown head, automatic charging system equipment components, ultrasonic cleaning machine, air heater, centrifugal fan, screw extruder, melt blown web forming machine, melt blown offline winding machine, melt blown offline slitting machine.

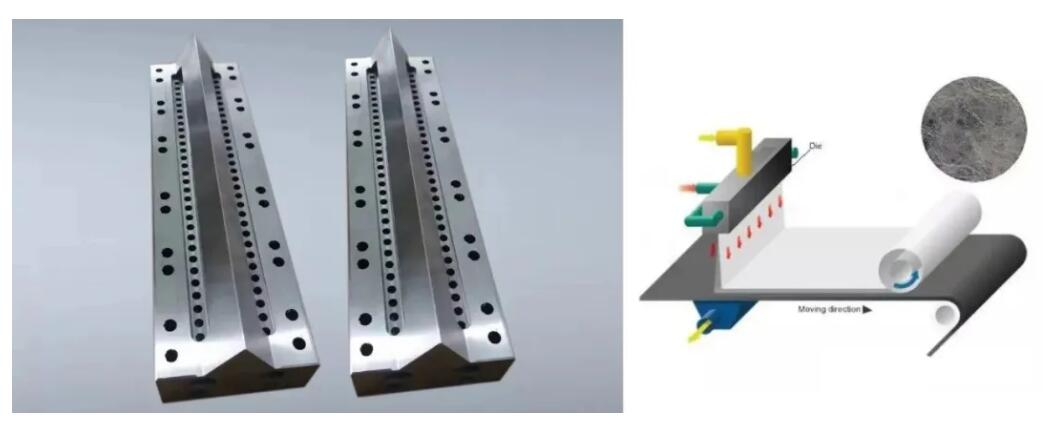

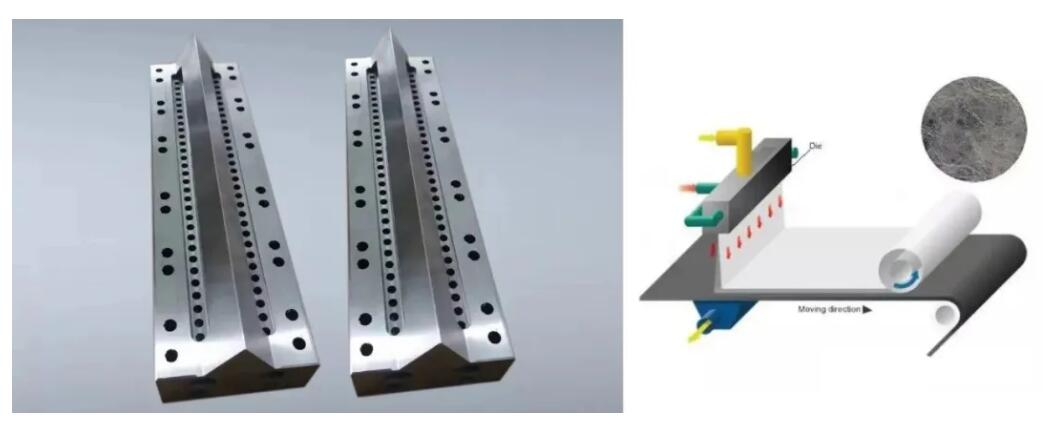

The core component of melt blown cloth equipment---spinneret

The spinneret for melt spinning is a representative spinneret for the manufacture of synthetic fibers such as polyester and nylon. The thermoplastic resin is heated and melted, and it is extruded through the spinneret in air or water at a certain speed and cooled. Spinning method that solidifies into fibers.

The core technology is the small nozzle on the spinneret. This nozzle is not only small in size, only 0.15mm, but also has a complex hole pattern on such a small nozzle, which is extremely difficult to process, and the nozzle processing process requires Several months. If the processing accuracy is not high, the final meltblown cloth produced will not meet the corresponding technical requirements, which will affect the protective performance of the mask.

Structure of melt blown cloth spinneret

The structure of the spinneret is divided into three forms according to the shape of the spinneret, round, fan and rectangular. At present, circular plates and rectangular plates are used more at home and abroad. In order to be suitable for different kinds of chemical fiber spinning occasions, round spinnerets are divided into flat plate type, flange plate type, plate ring, flange ring, etc.: rectangular spinneret is divided into flange rectangle and flange groove rectangle, etc. , It is mostly used for short fiber spinning with more holes.

Melt blown cloth spinneret structure

Meltblown die head

The die head includes a die head main body, a spinneret and an air plate. The spinneret and the air plate are detachably installed in the die head body. There is a spinneret hole in the spinneret, and there are several gaps between the spinneret and the air plate. There are several gas circulation channels in the main body of the die head, and the gas circulation channels are connected with the gap groove. The outer wall of the die head body is provided with a gas pipe connection end, which is connected to the gas collection cavity through a gas pipe Through, one end of the spinneret hole of the spinneret is fixedly connected with an interval flow stabilizing piece, and the other end of the spinneret is fixedly connected with a pipe connection device. The spinneret hole is connected to the discharge port of the screw extruder through the pipe connection device Connected.

In meltblown equipment, meltblown die is one of the core components to realize high polymer wire drawing. The design and accuracy directly affect the length, uniformity, toughness, fineness and many other aspects of the wire drawing, thereby affecting the quality of the final coil. Have a decisive impact.

Meltblown die head structure

Melt blown air heater

That is, the pipeline heater is composed of a body and a control system. The heating element is made of stainless steel pipe as a protective sleeve, high temperature resistance alloy wire, crystalline magnesium oxide powder, formed by a compression process, and the control part adopts advanced digital circuits and integrated circuit triggers. , High back pressure thyristor and other components constitute an adjustable temperature measurement and constant temperature system to ensure the normal operation of the electric heater.

Melt blown air heater

Polypropylene materials are extracted from petroleum. Currently, Sinopec and other companies can produce them in large quantities, but the equipment that produces polypropylene as melt blown cloth, especially the core components and spinnerets, mainly depends on imports. These suppliers mainly include Japan's Kasen spinneret, German Enka, and Japanese spinneret. Japanese suppliers occupy the most important position. With the current output of several companies, it is far from satisfying the market demand.

Therefore, the production capacity of masks ultimately depends on the output of the melt blown cloth production equipment, and the core spinneret nozzle of the melt blown cloth production equipment is very difficult to produce. The processing time takes several months, and the output cannot be greatly increased in a short time. And the production capacity is very limited, which also makes the mask production can only maximize the use of current equipment and increase production by extending the working time of the production line.

Main device configuration

1. Screw extruder; 2. Metering pump; 3. Melt blowing device; 4. Receiving net; 5. Winding device; 6. Feeding device.

The equipment of the continuous production line of meltblown nonwovens is about 6m high, 5m wide, and 20m long. The production equipment is as follows:

(1) Screw extruder: The screw diameter is generally 100~120mm, and the length/diameter ratio is 30. Its purpose is to melt the slices.

(2) Metering pump: Its function is to accurately measure, control the output and the fineness of the fiber. It is a gear pump that continuously delivers the melt to the spinneret.

(3) Melt filter: Its function is to filter out impurities in the melt to avoid clogging the spinneret holes.

(4) Conveying net curtain: The melt blown fiber is evenly received and spread on the net, and transported forward. There is a suction fan under it to discharge the hot air coming down from the top.

(5) Spinning box: It is the key equipment of the melt-blown process. There is a strip-shaped spinneret, which is covered with a long row of spinneret holes. Generally, there are about 1500 nozzle holes per m. The two sides of the spinneret are equipped with hot air nozzles, and there are hot air nozzles underneath, which form an angle of 50b with the nozzle holes. After the fiber is ejected, the high-speed hot air is used to stretch the air flow immediately to blow the fiber and become superfine fiber.

(6) Feeding system: It is composed of 3 measuring hoppers, which are used to measure white slices, masterbatch, and additives. The 3 components enter the mixing mixer below to mix evenly, and then put into production.

(7) Hot air blower and heater: provide the temperature and pressure of the hot air used in the spinning airflow drawing, use electricity to heat, and consume a lot of power.

(8) The coiling machine adopts automatic coiling, and the melt blown cloth is packaged in rolls. Meltblown nonwovens are characterized by ultra-fine fibers, and the smallest fiber diameter can reach 0.5Lm, generally between 1~5Lm. The finer the fiber, the better the quality of meltblown cloth, but the output is relatively reduced. Because the fiber is ultra-fine, its specific surface area is large, and the adsorption capacity is strong, which is the most prominent advantage of melt blown cloth.

If you are interested in melt blown fabric making machines then you can visit the link for more detail and video demo below:

https://www.troysupply.com/1200-1600mm-width-melt-blown-fabric-machine_p130.html

Many Thanks from TROY !

105.98.34.13

2022-08-07 05:56:41

105.98.34.13

2022-08-07 05:56:41

Online service

Online service 4000988557

4000988557 sales1@troysupply.com

sales1@troysupply.com sales2@troysupply.com

sales2@troysupply.com Richard Liu

Richard Liu TROY

TROY 8936906

8936906 Troysupply_com

Troysupply_com