The 5G era has arrived, but the construction industry is still one of the industries with the lowest degree of digitization and automation. While other industries are stepping up "smart addition", the "big but not good" construction industry is still at the level of "moving bricks, tying steel bars, pouring concrete, and installing formwork".

Ding Lieyun, a representative of the National People's Congress and an academician of the Chinese Academy of Engineering, said: "my country's construction industry has created many world firsts, but it also faces problems such as poor product performance, huge waste of resources, outstanding safety issues, serious environmental pollution, and low production efficiency." Karma has reached the time when it must be changed.

Unmanned excavator

Through the introduction of the chief engineer of the unmanned driving research and development center, the mystery of unmanned driving is slowly revealed: unmanned driving equipment adopts technologies such as environment perception system, intelligent motion control system, intelligent product cloud control platform, and issues instructions through the cloud platform. According to the image recognition, the location of the material will be judged to complete the work autonomously. In addition, the unmanned equipment has no limitation on the working hours and can operate 24 hours a day, 7 days a week.

Country Garden: Fully use robots to build houses next year!

In late August, at Country Garden’s interim results conference, Country Garden President Mo Bin said: “Construction robots will be profitable next year.” Prior to this, Country Garden founder and board chairman Yang Guoqiang also mentioned at the July management meeting. : "We must go all out to complete the pilot project of robot building. From next year, we will all use robots to build houses."

Let's take a look at Country Garden's construction robots and auxiliary intelligent equipment-intelligent follow-up cloth machine

Look! Pink "tall man" smart follow-up cloth machine

Standing on the construction work surface, the standard floors of all the buildings in this project are cast from concrete pumped by it. The cumulative work volume has exceeded 22,000 cubic meters!

▲Intelligent tracking type of distributed cutting machine in operation

Concrete robot

In Shunde Country Garden Fengtong Garden Project

Held a handover ceremony, a human-machine collaborative construction system with construction robots as the core,

It was officially put into use on the front line, and the actual combat mode was opened!

▲The concrete robots are doing leveling work very well

▲Concrete robot is doing smoothing work

Features of concrete leveling and troweling robot:

Small size, light weight, flexible steering

High accuracy and small error (control within 0-5mm)

Vibration and compaction, the pulp lifting effect is remarkable

High degree of automation, greatly reducing the labor intensity of workers

▲Concrete leveling and smoothing robots are in operation

Through automatic spraying operations,

It can avoid the high fall risk of traditional spraying,

The maximum spraying efficiency can reach 300 square meters per hour.

▲The exterior wall spraying robot is in operation

A new generation of intelligent residential building automation construction platform "Automatic building platform"

▲Picture of self-elevating building platform

All positions of the whole machine have synchronous jacking function

Synchronous control system, fully automatic closed-loop control height difference

In the current industry, most building platforms

It takes 2-3 hours to lift a structural layer

The current building platform of this model is lifted to one floor

It only takes about 1 hour at the fastest

Time shortened by more than 1 times

▲Synchronous lifting function of self-elevating building platform

Auxiliary lifting tools

Adopt 8 powerful suction cups to carry together

A single suction cup can carry 100kg

Effectively improve the efficiency of manual operations, safe and efficient

▲Auxiliary lifting tool operation

External wall staggered polishing robot

Attached to the outer wall ring rail operation

Modular design, small size and light weight

Accuracy error ±3mm, maximum cutting depth of 10mm misalignment

Quick assembly and quick disassembly of grinding components and mechanical arm, strong versatility

The cutting and polishing process also has the function of dust collection

Standardized construction is efficient and environmentally friendly

▲Robot operation on the wrong stage of external wall polishing

External wall screw hole plugging robot

Attached to ring rail car operation

Precise positioning to realize automatic blocking

Overall efficiency increased by more than 3 times

Cover more than 90% of the outer wall

Sealing is dense, anti-seepage is reliable, and the finished product has a good look and feel

▲Robot operation for plugging screw holes in external walls

Exterior wall putty coating robot

During construction

Can automatically fit wall changes

Automatic adjustment and coating of the second case

The construction quality is high, and the overall efficiency is increased by 3 times

▲Robot operation of exterior wall putty polishing

Exterior wall primer spraying

Attached to ring rail car operation, high safety

The efficiency is about 2 times that of manual spraying

Effectively reduce the hidden health hazards to construction workers

Safe, reliable, flexible and efficient

▲Exterior wall primer spraying operation

Floor grinding robot, at the work site of the underground garage,

Workers in the construction industry can deliver construction tasks with one click on the tablet,

The floor grinding robot with a height of about 1.7 meters immediately starts autonomous operation,

Not only does it grind faster, but its efficiency is nearly three times higher than that of manual work.

It's still very clean, let the construction site bid farewell to the dust!

▲The floor grinding robot is in operation

Floor cleaning robot

At the dedicated robot passage on the first floor,

The floor cleaning robot is moving slowly,

Automated execution of the construction site

Cleaning up small rocks and dust,

The ground becomes as clean as new wherever it passes.

▲The floor cleaning robot is in operation

Measuring robot

▲Measuring robot at work

Indoor spraying robot

Floor tile paving robot

Wall tile paving robot

Intelligent spray maintenance system

Features remote control, autonomous coverage, etc.

Effectively absorb dust and particles in the air

Complete concrete curing work

At the same time, it can cool down outdoor workers

Improve the construction environment and protect the health of construction workers

Respond to the concept of environmental protection

▲Intelligent spray maintenance system

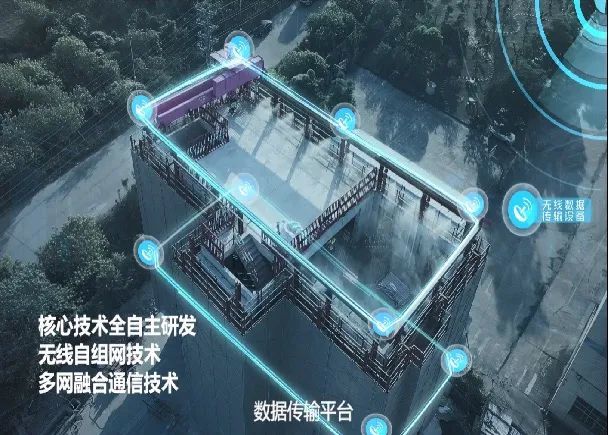

Intelligent detection system features:

Multi-network integration, strong coverage, more convenient information control

High safety and reliability, faster emergency response

Digital large screen integrated real-time broadcast

Simple deployment and more intuitive safety and quality supervision

▲Suggestion of intelligent detection system

Compared with the traditional construction method, the platform can easily realize the automatic operation of multiple processes such as high-altitude construction protection, construction layer leveling, troweling, and concrete curing while the main building is being constructed. All external wall actuators can be attached to universal rail cars and robotic arms, and only the actuator head needs to be replaced when working. When multiple buildings are being constructed at the same time, the horizontal turnover can also be realized, which is convenient, fast and easy to operate.

▲Traditional manual construction VS intelligent building robot construction

Compared with traditional manual labor, robot construction has significant advantages in terms of safety, quality, and efficiency. Under Yang Guoqiang's plan, in the near future, the intelligent construction factory will produce robot "workers" on demand. Through scientific planning, robots will enter the construction site in an orderly manner to complete the work and construction. Industrial workers will use smart technology software to operate and inspect all aspects of construction. Innovate production methods in the construction industry.

construction robot;

unmanned excavator;

Mobile cobot.

14.162.239.145

2025-06-12 08:50:34

14.162.239.145

2025-06-12 08:50:34

212.119.44.227

2025-06-12 00:45:27

212.119.44.227

2025-06-12 00:45:27

Online service

Online service 4000988557

4000988557 sales1@troysupply.com

sales1@troysupply.com sales2@troysupply.com

sales2@troysupply.com Richard Liu

Richard Liu TROY

TROY 8936906

8936906 Troysupply_com

Troysupply_com